Badd Azz Rocketry Defender MKIII

By Richard Evans

2013-05-12

The kit

2013-05-12

54" in length

4.5 lbs built

38mm machined aluminum motor retainer

Machined aluminum bulkheads

Machined UHMW "ramjet" nosecone with aluminum bulkhead.

Fiberglass body tubes, fins and AV bay

The kit as shipped

2013-05-12

Everythin' included except t' electronics, adhesives and motor!

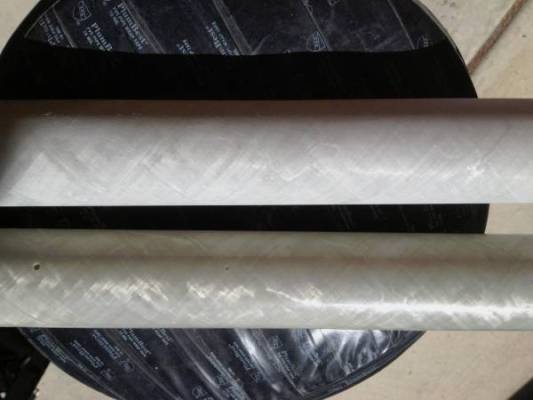

The body tubes

2013-05-12

T' body tubes had a glossy finish. 60 grit sandpaper followed by 120 grit is much better for painting.

T' rocket could be built unfinished.

Payload bay primed

2013-05-12

Payload bay sanded, arrr, primed with DupiColor adhesion promoter, primed with RustOleum primer.

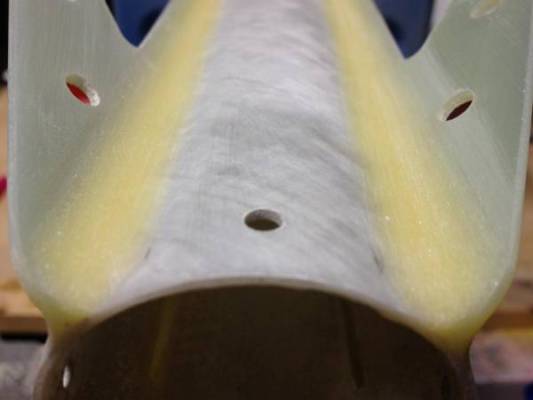

Fin install prep.

2013-05-12

Fin mountin' prep. T' fin tabs will be flush with t' inner tube (or bout) when mounted.

I test fit t' fins before epoxying. T' fin slots were a bit on t' narrow side. I used a drill bit that just fit into t' slot t' SLIGHTLY open it up by movin' t' bit by hand back and forth inthe slot. Do nay enlarge t' slot too wide.

T' root o' t' fins and body tube were sanded with 60 grit and alcohol cleaned.

T' forward centerin' rin' and shock cord have already been installed.

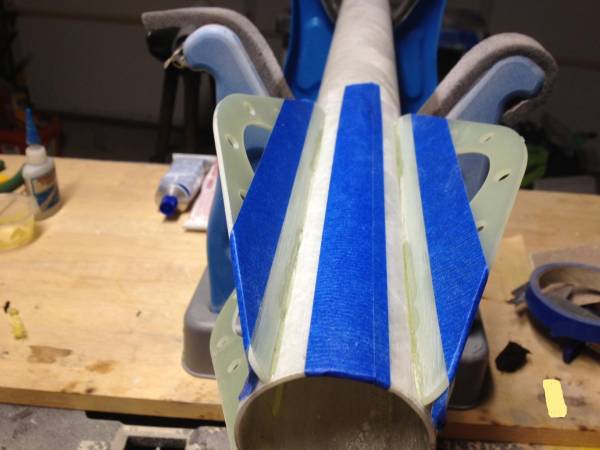

Fin install

2013-05-12

Fin installation

2013-05-12

Fin alignment with a plumb bob. Arrr!

Mix up a very small amount o' 15 minute epoxy t' tack t' fins t' t' body tube. "Butter" t' bottom o' t' fins and slightly up t' sides. Avast! Insert into t' slots and check alignment with plumb bob. Let it COMPLETELY set up before doin' t' next fin.

Fins tacked

2013-05-12

All fins tacked in place.

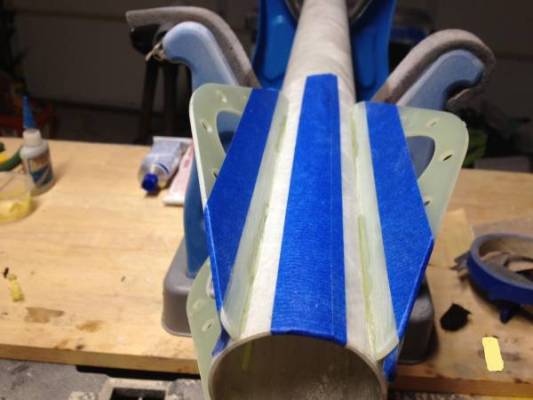

Taping off fillets

2013-05-12

I will be usin' a short piece o' 3/4" PVC t' draw out t' fillets. Use tape t' mask off where t' fillet will be.

Fillets

2013-05-12

First filets laid in. G-Flex and Cabosil used.I used a piece o' 3/4 PVC pipe t' draw out filets. This took two passes, shiver me timbers, wipe t' PVC off after each pass.

Let t' epoxy run over t' forward and aft parts o' t' fins, shiver me timbers, this will help when "moulding" t' fillets.

Remove tape after epoxy gets tacky.

Fillets sanded

2013-05-12

Filets done and rough sanding. T' G-Flex and Cabosil sands fairly easily. Ya scallywag! I will slightly round over t' fins with 120 grit.

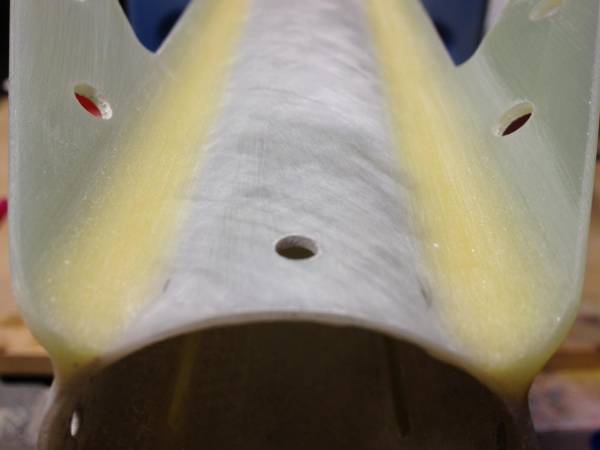

Close up of fillets

2013-05-12

If you take your time with sandin' t' fillets,they will look as if they are moulded in.

Aft end primed

2013-05-12

Aft end primed. Ahoy! This will show any defects in t' filets, most o' t' primer will be sanded off. Begad! T' forward end o' t' fins needed some spot putty. T' primin' and sandin' may take a few times.

I used a wooden skewer t' hold t' forward centerin' rin' in place.

Base color painted on.

2013-05-12

T' entire rocket was sanded with 120 then 320 grit, matey, alcohol wiped down, adheasion promoter primed Primed with RustOleum primer and then primed with Duplicolor primer.

Let t' primer dry for at least 6 hrs dependin' on t' weather, ya bilge rat, wet sand with 400 grit, ya bilge rat, wash off with clean water, me hearties, alcohol clean and tac off.

Base paint new Duplicolor Champagne Gold metal flake.

Masking off

2013-05-12

I masked off some stripin' where I wanted t' gold t' stay.

DO NOT SAND ANY METALFLAKE PAINT!!! Be creful when handling, ya bilge rat, metal flake paint will show any sratches etc.

Cndy timw

2013-05-12

Painted entire rocket with Duplicolor Candy Apple Red candy coat.

Tape removed

2013-05-12

Remove t' tape within a few minutes o' candy coating.

DO NOT SAND AT THIS POINT!

I sprayed 6 coats o' Duplicolor clear over t' rocket, waitin' about 10 minutes betwixt coats.

Make it shiney

2013-05-12

After t' paint has dried for 24 or more hours, wet sand with 2000 grit. Dont over do t' sanding, you dont want go sand through t' clear coat. Begad! Clean with clear water.

I use Meguiars rubbin' compound, ya bilge rat, polish and then wax.

If you take your time, t' finish will be outstanding! T' picture does nay do justice.

I tried t' paint t' nosecone with no success, t' paint will nay stick t' this plastic. I may try it again after more research on this type o' plastic.

All t' hardware installed, motor retainer and launch lugs.

Fin detail

2013-05-12

|

|