Estes M.I.R.V.

By Eric Lofgren

2016-11-08

| Manufacturer: | Estes  | |

| Diameter: | 1.6400 inches | |

| Length: | 24.5000 inches | |

| Skill Level: | 3 | |

| Style: | Multi-Stage |

As a first try at documentin' one o' me builds, I've decided t' photograph t' process o' buildin' t' Estes M.I.R.V., hopefully includin' some o' t' improvements suggested by Rich DeAngelis as I go.

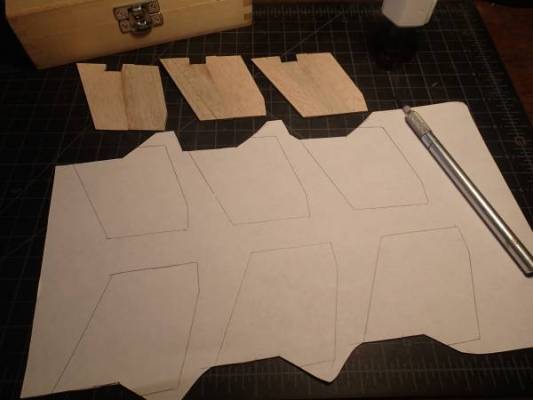

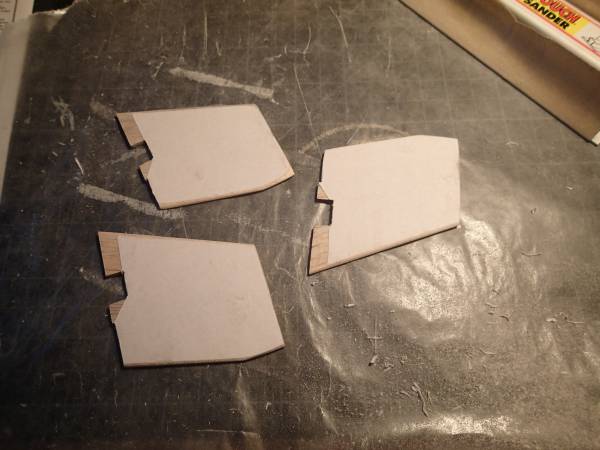

First stage fins

2016-11-08

T' three fins for t' first stage o' t' M.I.R.V. are in two parts each which must be glued up, me hearties, for no apparent reason other than t' use a smaller piece o' balsa. Blimey! My piece o' balsa on which these fin parts (parts A and B) were laser-cut was actually a glue-up o' two skinnier pieces. Aye aye! T' seam actually goes through a few o' t' fins. Blimey! One o' t' pieces must have been much denser than t' other, because on half t' sheet, t' laser cuttin' utterly failed t' make it through t' wood. Thus I spend longer than usual cuttin' out these fins, then I spent some time tryin' t' match t' pairs for weight. Well, blow me down! Sanded edges, glued up with Elmer's Carpenters Glue, and sat under a few volumes o' t' Grove's Dictionary o' Music and Musicians (5th edition) t' dry.

While waitin' I also glued up t' two pieces (H and G) o' t' stagin' manifold, usin' quite a lot o' model cement (at t' suggestion o' Rich DeAngelis). Avast, me proud beauty! I used Duco Cement with t' green label, which is indicated "good on phenolic plastics," nay polystyrene plastics.

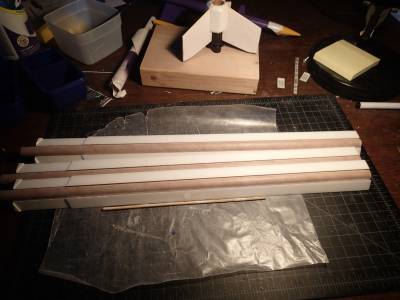

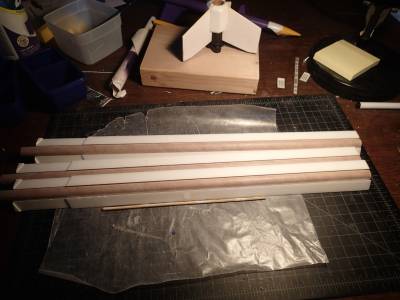

Booster motor mount

2016-11-08

T' next step be t' assembly o' t' lower (booster) motor mount. Aye aye! Since I read that others had trouble slidin' t' motor tube into t' foam mount before t' glue set, I decided t' help myself a little bit. While t' glue dried on t' motor hook, matey, I drilled a 3/8" hole in a piece o' 2x lumber (cedar, I think). Arrr! This let me put t' motor mount tube flat on a surface so I could push t' foam piece straight down until flush, without pausing. Begad! I also used yellow glue which doesn't seize quite as smartly in me experience.

Then I glued t' plastic part on t' top:

T' next few steps will involve paperin' t' lower fins.

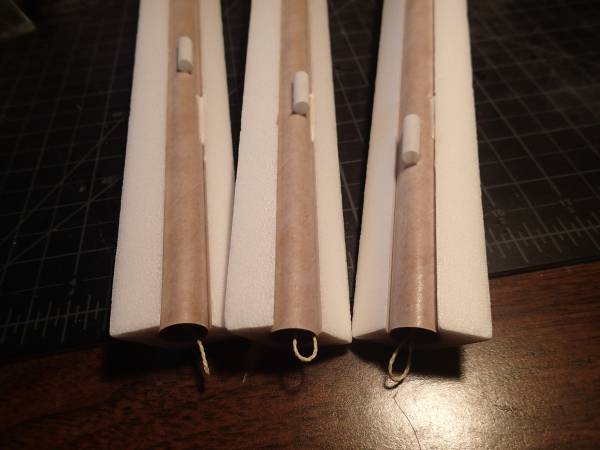

Booster stage fins

2016-11-10

I started workin' on these fins - they tuck into slots in t' foam so I wanted t' leave a bit o' t' root edge unpapered. I cut a notch from t' paper before gluing, me hearties, spread white glue-all, rolled out t' excess, me bucko, trimmed and sanded t' size. Begad! I used elmer's wood glue at t' aft end o' each fin and duco cement at t' forward end where it contacts t' plastic part. Ahoy! I'm leavin' t' launch lug standoff off for now; it's rectangular and I'm nay sure which way it goes, plus I may have over-sanded it and I want t' make sure it aligns with t' upper lug when I get t' it. T' next step after that is supposed t' be addin' a 3/16" dowel for t' upper stages, which I'd like t' make longer, so I'm goin' t' hold off on that too.

Beginning body tubes

2016-11-11

A quick update - gluin' t' BT5 body tubes into t' styrofoam body segments, arrr, and gluin' t' plastic nose cone halves together. Ahoy! Next is all t' fins for t' upper stages, nine total, three o' which have t' be glued from smaller parts. I'm plannin' t' paper all o' them.

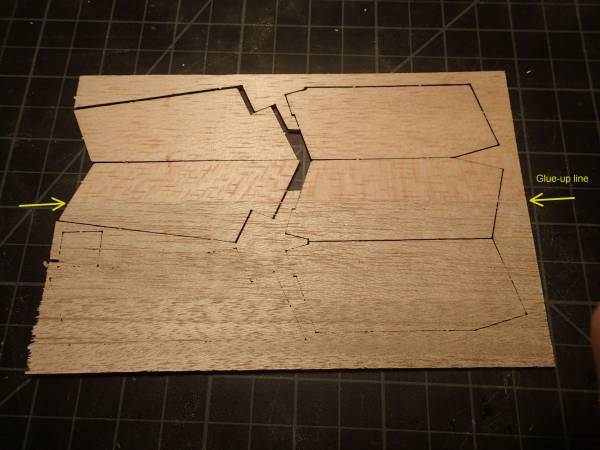

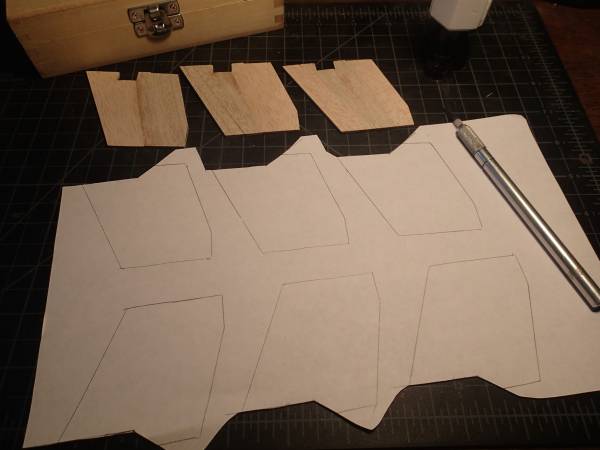

Upper stages fins

2016-11-12

For no apparent reason (again), shiver me timbers, three o' t' nine upper fins have t' be glued together, so I did that first.

Paper on all nine fins then required a portion o' t' edge t' be left uncovered, but on these it was a straight line, matey, so I just glued them off t' edge o' t' paper.

Same deal for t' other three

While I waited I glued in t' engine blocks; next I'll install t' dowel and launch lugs so I can get t' fins lined up right.

Internal launch lugs and fins

2016-11-14

With t' fin paperin' complete I cut a long 3/16" dowel (probably around 16-17") t' use instead o' t' one in t' kit. I positioned t' launch lugs near t' top t' hold t' nose together more securely.

That done I began attachin' t' fins. Blimey! I glued one o' each pair o' fins, then used t' assembled rocket t' align t' other three.

T' third fin on each sub-rocket is easy, matey, just stick it in t' slot. Ya scallywag! With t' internal rod assembly complete, I was able t' confidently attach t' lower launch lug standoff.

Shock cords

2016-11-18

I borrowed some ideas from various places for me shock cord mounts. I poked a hole through t' body tube and fed some kevlar through, then glued it down in t' crack betwixt t' foam and t' BT. Once dry it feels plenty strong.

That done it's time t' start finishing. I started with a coat o' Krylon "Craft Foam Primer" that I found at Michaels. It's weird stuff, seems very watery, matey, but it didn't eat t' foam and it sands OK. Well, blow me down! I'm tapin' off and primin' t' fins with me usual rustoleum grey primer.

Painting

2016-11-21

Havin' painted t' entire rockets with Krylon "Craft Foam Primer", and then t' nose cones and fins with Rustoleum grey auto primer, arrr, I top-coated t' entirety with Krylon Black "Shimmer Metallic" and while it for t' most part looks good I had some weird bubblin' on one o' t' nose cones that I'm goin' t' have t' sand down and redo. Avast, me proud beauty! Unfortunately t' temperature dropped by over 30 degrees (F) over t' weekend and so paintin' is temporarily halted. Arrr! I need t' do t' red bits too for t' factory look. I've started work on a FlisKits Trifecta in t' meantime.

Decals

2016-12-06

I finished t' paint and got t' decals today. I'm, me bucko, as usual, ya bilge rat, disappointed in Estes decals. They include only enough t' cover t' rocket from one angle, t' angle they use for t' photo. Begad! It's like when you see a fast-food burger on TV and you know they've scooched all t' veggies t' t' camera side o' t' bun so it looks better. So, for example, shiver me timbers, I get four o' t' red and white roundels. Six would be good and is "implied" by t' cover art. Begad! This kit had another problem which is that t' decals used for t' advertisin' pictures are much larger than t' ones included. Here's a picture from jonrocket.com:

T' roundels take up t' whole fins (indeed, they don't even fit). See t' yellow decals which seem t' attach t' parts together? (note: I got five o' these. Plenty o' room for six on t' sheet!) And see t' "windows" near t' nose cones?

Now here's me rocket:

I'm addin' crepe-paper streamers t' all four parts (not sure t' one twisted around t' internal launch rod will work, shiver me timbers, but I'll try it). Begad! Hopefully I'll get a launch in this weekend.

New Years Launch

2017-01-01

We had a beautiful day today and I was able t' launch several "new" rockets includin' t' M.I.R.V.

I used a B6-0 and three A10-3T. Ahoy! All four pieces had red crepe-paper streamers t' help with recovery, shiver me timbers, and I be launchin' on a snowy cornfield so I had high hopes.

T' rocket weathercocked a lot durin' t' booster stage, then all three upper stages launched perfectly, but a bit horizontal and straight into t' sun, and all three appeared t' spiral off. (They did nay stay together at all, like others have observed.) We heard t' "pop pop pop" o' three ejection charges firing. I completely lost track o' t' booster somewhere in here. We took off runnin' t' find all t' pieces; t' first two were found smartly but t' third had torn its streamer and took us a long hunt before me five-year-old stumbled across it. Well, blow me down! T' booster was found just downwind o' t' launch pad, maybe 15 feet away.

This was a nail-biter o' a launch but all went well and I can recommend this rocket if you can stand t' cost o' usin' four engines on every launch.

I would recommend t' addition o' streamers or anythin' else t' help find all t' parts after launch.

Stuck engines

2017-01-10

While I did recover all parts o' t' M.I.R.V. Aye aye! I have found t' mini engines got severely stuck in t' upper-stage body tubes. One came out after an overnight out in t' garage but two are still stuck. Begad! Don't add any extra tape t' make them friction fit! T' wrap on t' outside is plenty.

|

|