Estes Pro Series 1 Jayhawk

By Lester Anderson

2014-11-29

I am buildin' up an Ebay find. Ya scallywag! This is a 1/5 scale model o' t' Jay Hawk Supersonic target drone o' t' 1960's and 1970's. It is about t' same size as t' current Mad Cow Jay Hawk kit, 2.5 in dia. Blimey! body tube for t' Estes vs. 2.6 in dia. Arrr! for t' Mad Cow.

Parts

2014-11-29

As can usually be expected with an open EBay buy, ya bilge rat, parts were missing. I ended up havin' t' re-cut all t' centerin' rings, because t' originals were nay included. I also had t' re-cut t' rudder fins, also missing. Begad! T' me good fortune, matey, thar be a lot o' wasted space on t' win' sheets. I moved t' "ailerons" t' a different spot, and cut 2 pieces o' rudder from each existin' sheet, ya bilge rat, still leavin' enough balsa t' re-cut t' ailerons also. Begad! Thank goodness for YORP, which has t' instructions, fins, shiver me timbers, and decals all scanned in a pdf file.(http://www.oldrocketplans.com/estes/est2085/est2085.pdf) Other than that, shiver me timbers, it is what you might normally expect from 20 year old parts. Avast! Blimey! T' glassine has yellowed, as has t' nose cone. Begad! Blimey! T' vacuum formed parts still look good. Begad! Blimey! And t' existin' balsa was still straight.

Engine mount and boat tail

2014-11-30

T' instructions start by havin' you make t' aft boat tail. It is a simple paper transition glued t' itself. It was also one o' t' pieces nay included in t' EBay parts, so I ended up havin' t' cut out a replacement from some poster board I had layin' around. Ahoy! Blimey! I double layered it for makin' a even seam on t' outside, and a slight increase in strength.

Next comes some minor upgrades. Blimey! Bein' as all t' existin' centerin' rings were missing, me bucko, I needed t' make new ones. Avast! This was accomplished by drawin' them up with Autodesk's design program 123D Beta 9. Aye aye! Autodesk does nay support this anymore, but it be t' most versatile 2 and 3D design program I have found for t' freeness o' it. Blimey! After the drawin' was done, I took t' design (converted into a PDF file on a flash drive) t' me local FabLab t' use their laser cutter. Wonderful tool, made parts that were perfect t' first time.

I also made a retainer rin' t' help hold t' engine hooks in place. This used t' be t' 24mm aft centerin' ring, ya bilge rat, which I repurposed. Aye aye! I decided t' upgrade t' a 29mm motor mount.

Next, matey, I dry fit everythin' together t' see if it still looked right. Arrr!

Next we move on t' gluin' it all together.

Motor mount assy.

2015-01-13

Well, ya bilge rat, now that t' holidays are over, it is time t' add more entry's t' this build. Avast! We left off with dry fittin' all t' motor mount pieces together. Next came gluin' it up. Begad! I used Gorilla brand wood glue. I only plan on launchin' this on a 29mm G engine at t' most, so I figured with 2 plywood centerin' rings backed up by 2 Bristol board centerin' rings, I believe I have plenty o' surface area t' grip to.

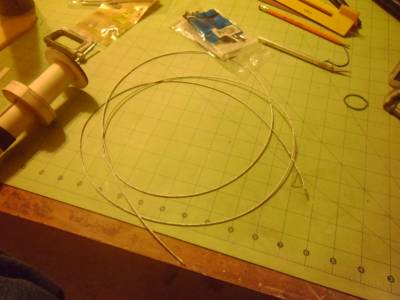

Next we need t' attach a shock cord anchor t' this beast. I used 1/16 galvanized braded steel cable from me local Lowe's hardware store, matey, secured with a couple compression fittings. Avast! T' cable was covered with electrical heat shrink tubin' t' prevent t' cable from snaggin' on me shock cord or parachute.

T' base o' t' anchor has a piece o' 3/16 dowel wrapped in about 8 layers o' aluminum foil tape t' spread out t' ejection forces on t' centerin' ring. T' dowel is secured with a little more aluminum tape.

All that's left is t' glue on t' aft boat tail, me hearties, then glue it into t' body tube. Arrr!

T' aft tail cone has a few ripples from where t' rubber bands held it together while t' glue dried. I will be fillin' all that with some wood filler and sandin' it smooth.

Fins

2015-01-13

Ok, I admit it. Blimey! Over t' holiday's I did some work and forgot t' take pictures. Begad! I ended up almost completely workin' t' fins t' completion before takin' any pictures. Avast!

This would be t' Rudders, ailerons, and main wings. Blimey! As you may notice, t' wings are 4 different pieces o' wood. T' "thru t' wall" tabs are from t' fin sheet, lockin' into t' motor mount assy. T' leadin' edge is a piece o' model airplane trailin' edge stock, which t' instructions have t' matin' surface sanded t' make it "arrow" shaped. Avast, me proud beauty! This way, matey, thar be an equal bevel on top and bottom o' t' win' when it is glued on.

Next are t' Rudders. These are 2 piece assembly's. Glued together at t' root edge, and beveled at t' leadin' and trailin' edges t' a 45 degree angle. I found t' easiest way t' get t' 45 degree angle was t' stack t' fins together with a 1 material thickness space on t' leadin' edge, ya bilge rat, then sand a surface across t' exposed edges till smooth. T' leadin' edge is easier than t' trailin' edge because o' t' included angle on t' trailin' edge.

And t' ailerons. Avast, me proud beauty! Kind o' small, matey, and difficult t' contour correctly.

These ailerons have t' wrong profile on them. Well, blow me down! They were too short t' properly bevel t' leadin' edge t' a 60 degree angle. That same shortness prevented me from bevelin' t' trailin' edge at an even taper from t' front bevel t' t' trailin' edge. My solution was t' re-sand t' leadin' edges t' a sharper angle, matey, assemble t' ailerons t' t' wings, shiver me timbers, then sand t' trailin' edges t' a finer taper.

T' first picture here is o' a detail on t' outer edge o' t' wing. It is simply a match stick glued into t' factory cut edge. Ahoy! It's purpose is t' hold he aileron in place while t' fin is bein' assembled. T' only other gluin' surface for t' aileron be t' aft tail cone, because o' t' sharpness o' t' aileron's leadin' edge. Avast! I plan on laminatin' t' entire win' assembly with paper and epoxy for strength next. Ya scallywag!

Wing & rudder assy.

2015-04-18

Just a couple pictures o' t' main win' assy. Ya scallywag! I used a little thin CA t' tack t' rudders t' t' end o' t' wings, then some epoxy mixed with microballoons t' fillet the joint. Next, laminatin' t' wings with paper and epoxy for strength.

a little bit o' detail from t' fins. One has been sanded, t' other has not.

Fin and body attachment

2015-05-17

Wings / fins are now epoxied to t' main body tube. Arrr! T' fillet's need some touch up sanding, me bucko, as do t' tips o' t' rudders.

. .

.

Equipment bay

2015-07-15

Finally got back t' buildin' this. Well, blow me down! I glued t' bottom blow molded equipment trough t' t' main body. Avast! I'm still debatin' with myself if I want t' add fillet's t' smooth out t' bottom edge o' this decoration.

Nose cone.

2015-07-24

This nose cone takes a bit o' work t' put together for this model. Begad! It has antennae t' glue t' it, t' leadin' edge o' t' equipment Bay, and t' two elevators that t' original missile had. I started by gluin' t' antennas on t' it.

Next, me hearties, I glued on t' forward end o' t' equipment Bay with thin CA glue.

And lastly we go on t' elevators. Avast! These were two piece Affairs that needed t' be glued together before they were attached t' t' nose cone. Due t' every other review that I had seen showin' that these elevators were a weak point o' t' nose, they are completely filled with West systems epoxy for gluin' onto t' tabs that they hold on to. Even t' inside o' t' tabs was filled with epoxy.

All that's left now is t' smooth everythin' out in prep for primer.

Painting and Decals

2015-08-09

well I didn't take any pictures betwixt primer and paint. Sorry about that for those o' you have been watching. All in all t' paint turned out pretty good this time.

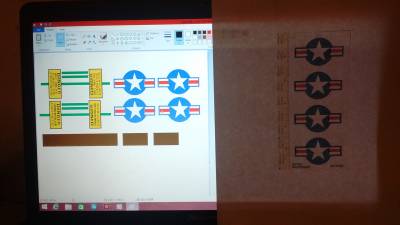

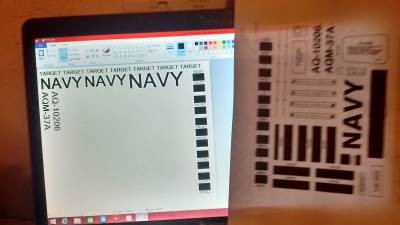

I also decided t' redraw all t' decals. Avast, me proud beauty! T' scans provided by T' Olde Rocket Plans took up a lot o' space on a 8.5x11 sheet o' paper.

Last Entry

2015-08-29

well well this entry is finally done. Begad! It's taken me t' longest o' any model t' build this Jayhawk. This is a primary reason I don't do scale models because they do nay fascinate me. So here are some pictures t' show it is complete.

|

|