Mega Daddy 29

By Christopher D. Shramko

2016-01-18

Kit-bash o' Estes Big Daddy, Aerotech Initiator packin' tube, and Aerotech 29mm Motor Mount. Inspired by t' 3D Mega Daddy, me bucko, me son prepared a RockSim design with separation at t' Big Daddy "Fin Can" t' Aerotech Initiator shippin' tube "Main Body Tube". We've ordered way too many bits and pieces from Apogee, matey, JonRocket, and eRockets. Aye aye! Dry-fit soon. Begad! See also Mega Daddy 29.

This is Part I. Begad! See also Mega Daddy 29 - Part II.

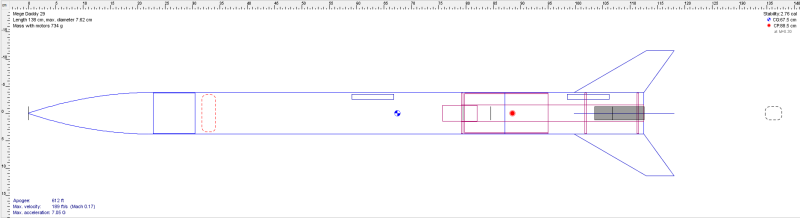

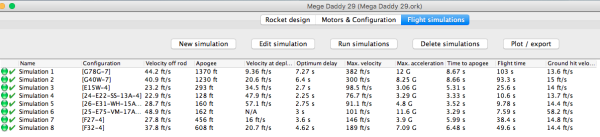

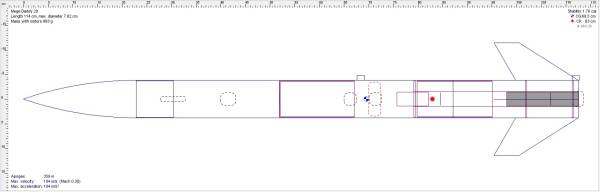

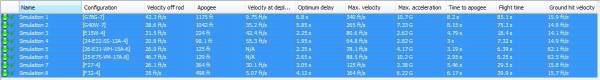

OpenRocket Proof of Concept

2016-05-19

Our build blog entries are laggin' behind our work, which is laggin' behind our schedule, me bucko, but we are catchin' up!

Here is our quick OpenRocket Proof o' Concept Study t' show that t' basic design is feasible.

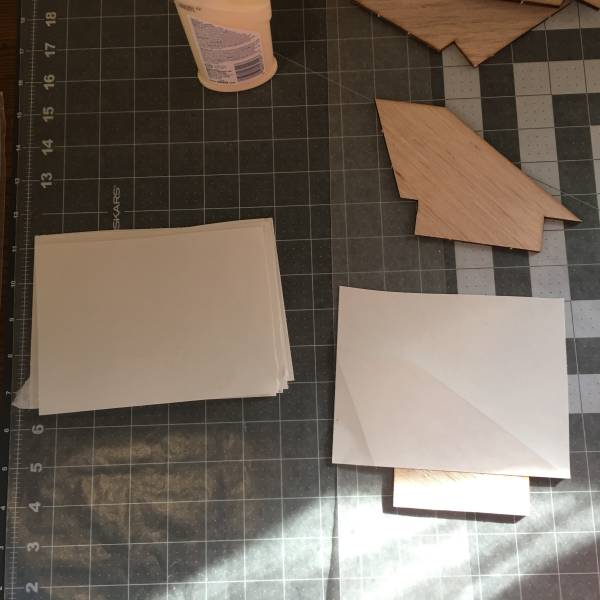

Bits & Pieces

2016-05-23

Parts from t' Estes Big Daddy kit surroundin' t' Aerotech Motor Mount kit.

T' Estes parts on t' left were added t' our spare parts bin.

T' parts on t' right were used for this build (Body tube, nose cone, me hearties, and fins).

So many options for our launch guide: heavy duty 1/4" launch lugs, surface-mount rail guides, or rail buttons?

Shock cord: Apogee bungee cord or Aerotech flat shock cord?

Centering-rin' dilemma: Is t' motor mount tube considered thick or thin wall?

Is t' body tube thick or thin wall, or heavy duty cardboard?

By 3" tube do they mean inner or outer diameter?

There were so many options that we purchased a few hopin' for as little sanding-to-fit as possible.

T' Aerotech motor mount tube seemed t' call for an Aerotech motor retainer.

Aerotech 1.9" 3-fin motor mount kit. We used t' tube, baffle, me bucko, screw eye,

and coolin' mesh in this build and put t' rest in our parts bin.

Bulkheads & Hardware.

Display stand (which would turn out t' be undersized for this build) and chute-protector (it can't hurt,

might help if we can afford a Chute Release, arrr, and might be necessary if we drop t' coolin' mesh and baffle).

Pins & Swivels.

T' far-too-big-for-this-application u-bolt.

Poster board for skinnin' t' fins.

We are cringin' over our failure t' rotate all images t' t' same orientation,

but at least we managed t' keep them in focus and avoid fingertips in t' corners :)

Dry-Fit of Fin Can and E-Bay

2016-07-11

We dry fit different combinations o' parts t' find which sized o' centerin' rings, matey, bulkheads, shiver me timbers, etc., were required, and t' see how much material we would need t' remove from t' through-the-wall fin roots.

Motor Mount Assembly

2016-07-11

Installation o' middle centerin' rin' and coolin' mesh t' motor mount tube, and top centerin' rin' t' tube coupler.

Tube coupler dry-fit on motor mount tube.

Motor mount and tube-coupler dry-fit into fin can.

Shortenin' tube coupler t' twice t' exposed length t' save weight.

Shock-cord screw-eye installed into motor mount tube baffle, then beveled t' bottom edge.

Tube coupler mounted t' motor mount tube; removed length o' coupler on table for comparison.

Motor mount installed in fin can, baffle installed in motor mount tube, and top centering-rin' coated with epoxy.

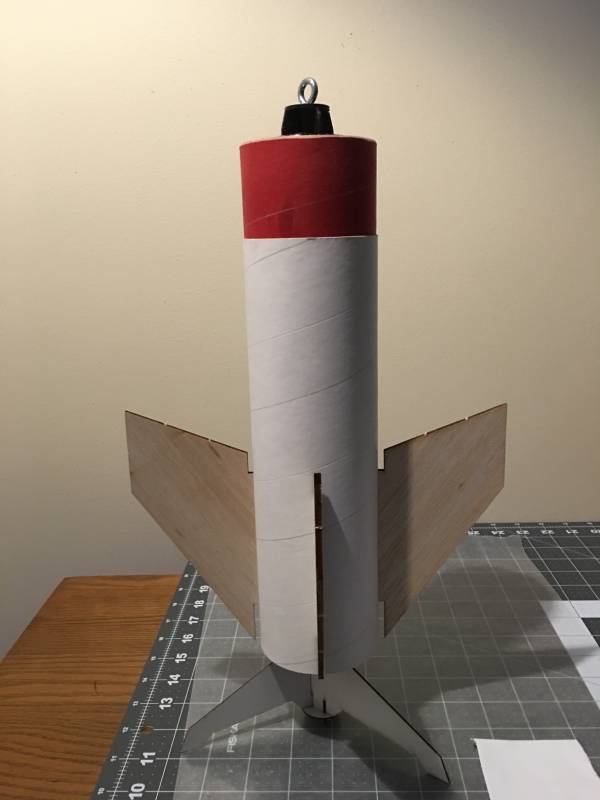

Fin can on display stand, ya bilge rat, with dry-fit o' fins in swept-forward configuration (to reduce fin damage on landings).

Body Tube

2016-07-12

Nathaniel really can't wait t' get his L1 certification and t' start usin' electronics bays with dual-deployment. He realizes that he is too young for L1, but would like his rocket t' "be ready" for when he is old enough. He is also concerned that we've added too large a volume t' t' rocket body for engine deployment, and he doesn't like stuffer tubes, me hearties, so we're puttin' in an e-bay with only one bulkhead t' act as a volume reducer; we can always complete t' e-bay build later.

Wrap with marks transferred from two o' t' fin cut-outs. Ya scallywag! We then folded in half, alignin' t' marks, t' find t' mid-point for t' rail buttons, then transferred this mid-point back t' t' fin can for t' "LL" line.

Drawin' lines on t' body tube for rail guides, e-bay rivets, me hearties, and nose-cone shear pins.

Dry fit o' body tube and nose cone. Ya scallywag! E-bay with lower bulkhead and shock cord eye alongside.

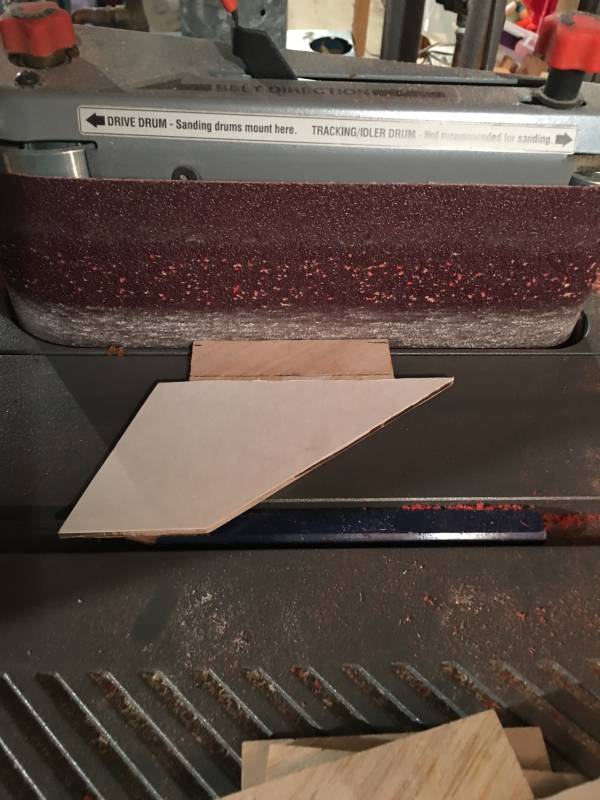

750 revolutions o' 120-grit paper for a proper fit betwixt t' fin can and body tube. Next time we sand on t' oscillatin' belt sander before installation.

Shear pins at mid-point o' nose-cone shoulder and registration mark.

Paper wrap t' mark t' mid-point o' t' e-bay on t' body tube for locatin' rivets.

Rivets installed.

Locatin' t' upper rail button. Top line is bottom o' e-bay; bottom line is twice intrusion o' fin can. X marks t' middle o' t' two. Why? Because we wanted t' avoid interference with either, and our personalities required a calculation

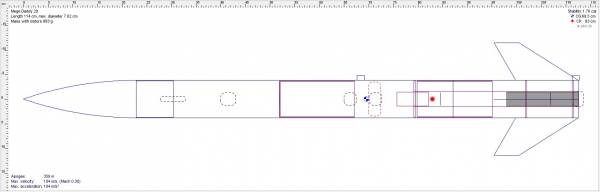

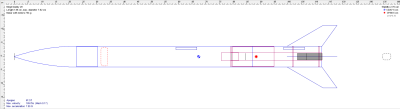

Open Rocket Design Revision 1

2016-07-12

Electronics Bay

2016-07-12

Our electronics bay will initially have only a lower bulkhead, fixed t' t' bay tube with epoxy fillets. This bulkhead will have two screw deadlights t' accept t' upper and lower shock cords. Aye aye! We are installin' a just-long-enough-to-reach length o' shock cord betwixt t' e-bay and t' nose cone t' prevent loss or ballistic re-entry o' t' nose cone should t' shear pins nay hold. Avast! Epoxy clay was used t' cover t' screw points t' prevent abrasion.

We lost some bristles from t' acid brush used t' apply t' epoxy. Begad! We could remove then with tweezers or tooth picks, shiver me timbers, but we prefer t' think o' them as "fiber reinforcement". Avast, me proud beauty! Note that t' e-bay tube has already been introduced t' t' oscillatin' belt sander.

Shock-cord installed and rivet holes drilled.

Fin Installation

2016-07-12

Paper skinnin' t' fins. Three external edges then coated with thin CYA glue.

Shortenin' t' fin tabs.

Post-shortenin' dry fit.

Fins installed with epoxy on internal and external fin roots.

Upright dryin' time. Ya scallywag! Many builds-in-progress in t' background.

After drying, we coated t' middle centerin' rin' with epoxy and painted on internal epoxy fillets where t' fins meet t' body tube, motor mount tube, and centerin' ring.

We then installed t' lower centerin' rin' with J-B Weld, me bucko, gluin' t' rin' t' t' fins, motor mount tube, and body tube. Arrr! T' lower rail button insert received coats o' J-B Weld under and over, then t' whole bottom (centerin' ring, inside o' body tube, arrr, and outside o' engine mount tube) received a brushed-on coat o' J-B Weld and we slid t' motor retainer home. As we were excited over our almost-complete construction, me hearties, we neglected t' take pictures

Paint Scheme Test

2016-07-12

Here's t' assembled rocket with a whole can (4 coats) o' t' neon-est green paint we could find. As we're happy with t' results, thick-build primer, sanding, and more coats o' neon green will follow.

|

|