Orange Whip

By Ron Beard

2012-10-02

As promised, here be t' build, me hearties, with photos o' me level 1 cert. Begad! rocket. All props t' Larry Brand who inspired me with tales o' his own tube-fin experimentin' on this very site!

Lots o' home-made parts and low cash expenditure are t' hallmarks o' this great flyer.

Flys on G through J impulse motors so is good for Mid-power, arrr, Level 1 and Level 2 flights! (yes . Avast! . . Avast, me proud beauty! really!)

Basic Construction

2012-10-02

T' body tube is a standard Staples or Office Depot purchased, 4 inch diameter mailin' tube - about $12 ordered online. no special prep other than sealin' well with sandin' sealer and several coats o' paint.

T' tube fins are cut down 3 inch mailin' tubes o' t' same pedigree as above - 1 tube, about $5. Aye aye! epoxied lightly inside and out then sanded smooth t' prevent high-speed delamination

T' motor mount tube be purchased online and is a standard 38mm LOC MMtube. Begad! $4.00 online. 20 inches and open at t' end. Begad! Tube fin rockets have a weird CP/CG relationship which allows you t' pretty much stuff t' motor tube with as long a motor as you can find. Even a little extra pokin' out o' t' end is nay a bad thing. Begad! See Larry Brands excellent research on this subject on this site.

T' centerin' rings were hand made by laminatin' 2 layers o' 3/16 balsa with 3 layers o' heavy construction paper - maybe $2. Avast, me proud beauty! see a more detailed expalination at t' end o' this article.

T' nose cone was hand made usin' rings from 2inch thick DOW styrofoam wall insulatin' sheets and 3/16 balsa sheet rings then covered with a pantyhose and some 30 minute epoxy. - $8 bucks or so. Ya scallywag! Totally hand made without power tools/lathes etc. Massive pain in t' butt . Blimey! . satisfyin' in t' end but comes with a great case o' "tennis-elbow" from all t' sanding!

T' recovery system is braided Keelhaul®©™/standard braided nylon bungee cord/nomex chute protector/nylor chute. I had all o' this stuff on hand, but purchased - maybe $35.00

Finishin' and sundry bitz - $10

All up weight is around 36 ounces (plus whatever motor you use) and length is right at 3 feet. Flights tend t' be slower because o' t' drag effect o' t' tube fins and care should be taken t' simulate any flight you even think might approach 400 miles per hour or faster as t' design will most likely disintegrate at or above these speeds (it is just really cardboard and paper after all!)

So, for around $75 and a decent ammount o' work, you get a very versitile, interesting, durable flyer that should nay only let you certify simply and safely, but will continue t' be a fun rocket in your fleet and certaily one you can experiment on without t' "ouch factor" if you make a mistake (hasn't happened t' this one yet but I have some plans . Avast! . Begad! . Begad! MUAHAAHAAAHAAAA!!!)

-untitled-

2012-10-02

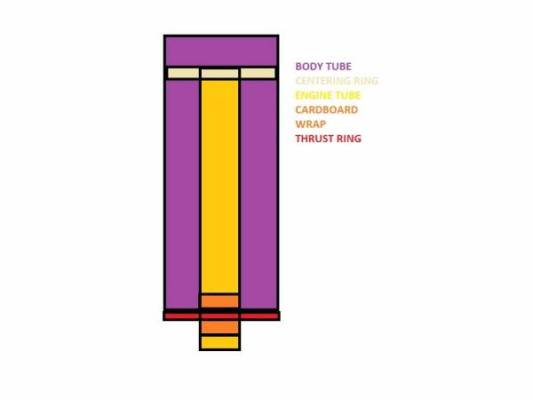

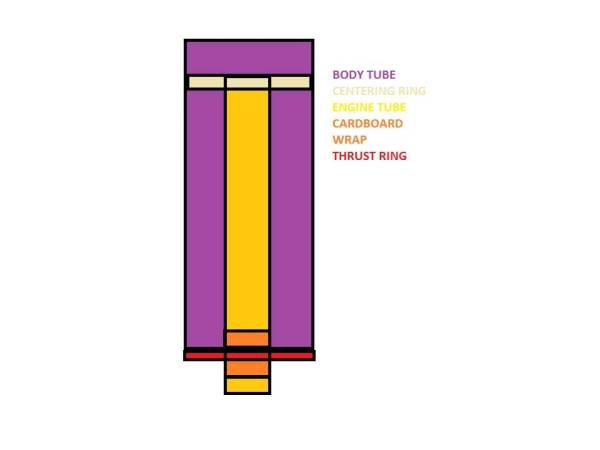

Of Note: Engine mount

2012-10-02

As mentioned above t' engine mount tube is standard LOC material but t' intallation is not. First, me hearties, t' centerin' rings were made by laminatin' 3/16 balsa sheet in betwixt layers o' heavy construction paper usin' Titebond II like this:

Heavy CP

Balsa

Heavy CP

Balsa

Heavy CP

A sheet o' this "poor-mans composite" material was created that would be big enough t' cut out 2 - 4inch rings from. Lay up t' sheets like you're laminatin' fins then press on a flat surface under a big ole stack o' books for a day or so. When finished, me bucko, trace out t' pattern and cut out t' holes for t' motor tube first then cut t' rings themselves out. Begad! Rough fit them t' t' end o' t' body tube makin' t' sure t' sand them a little bit "loose". Ya scallywag! I wanted t' front CR t' slide freely up into t' body tube as normal but then i decided t' aft rin' should act as a thrust rin' as well ands so sanded it just t' t' OD o' t' body tube itself. at this point, arrr, t' rings should be tacked t' t' engine tube with CA and don't forget a little relief hole in t' top rin' so you can thread a kevlar shock cord through! Since t' bottom rin' was also goin' t' act as a thrust rin' and have a great deal o' pressure placed on it by t' thrust o' t' motor, i wrapped t' engine tube 6 or 7 times, above and below t' aft rin' with a 1 inch strip o' construction paper and titebond. Ya scallywag! T' idea is that t' engine tube is so well adheared t' t' aft centering/thrust rin' that no failure due t' overthrust will occur. T' inside o' t' outside o' t' whole motor mount assembly be then epoxy coated and inserted into t' bottom o' t' body tube. Begad! I used a big batch o' 5 minute epoxy for this and then did a move i call "the twisty toss" which is where you toss t' body tube slightly into t' air while holdin' it vertically and impart a rapid twist on t' tube as you do it. Blimey! This forces t' epoxy t' flow onto t' inside walls o' t' body tube and after 3 minutes or so o' this, me bucko, things have pretty well solidified. Last but nay least, t' equivalent o' a 2 inch tube coupler (created by takin' a slice out o' an extra piece o' 4 inch mailin' tube so it fits down inside t' body) is pushed all t' way down so it buts against t' top o' t' motor mount assembly then epoxied in place. Arrr! This method creates a medium weight but uber bullet proof mount that, short o' t' material itself failing, will nay be defeated by even t' highest thrust 38mm motor I could stuff into it! See t' diagram below.

Post production:

2012-10-02

This rocket is completed and has flown well on a G-79 and an H-128. Begad! T' boost is always strait and t' rocket does nay weathercock much either. I will post a full review soon with more pictures from t' upcomin' "Buckeye Blast" November 10th 2012 (see torc703.org for details) where she will fly again maybe on an I or maybe even a J motor if I can find a donor case!!

|

|