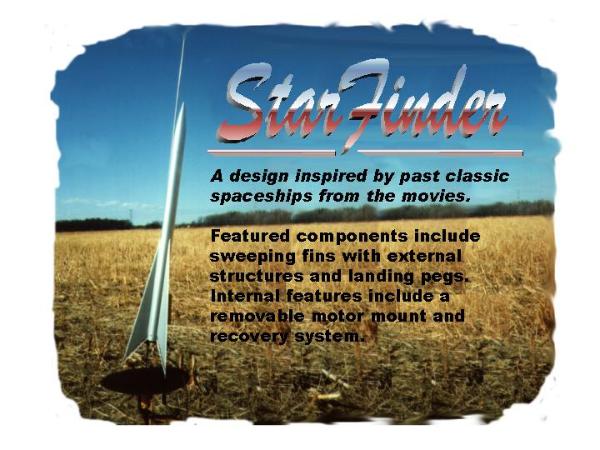

Scratch StarFinder Original Design / Scratch Built

Scratch - StarFinder {Scratch}

Contributed by Dan Bihary

| Manufacturer: | Scratch |

| Style: | Futuristic/Exotic |

Assembly Description

Parts

Body Tube LOC/Precision BT-2.56

Nose Cone LOC/Precision PNC-2.56

Motor tube LOC/Precision MMT 1.14

Coupler Material LOC/Precision TC-2.56

Fin Material 3/16" Aircraft Plywood

Fin Structure Plastruct 3/16"x 1/2" Truss

Landin' Pegs 1/8" Brass Tubing

Fasteners (6) Wood Insert Nut and Socket Head Screws

See rocket dimensions and stations here

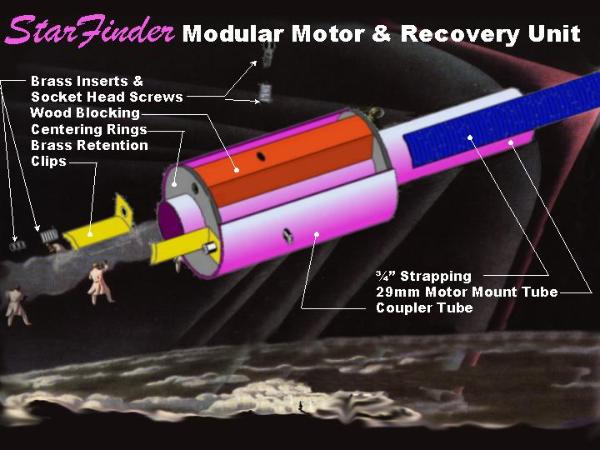

Modular Motor Mount Retention Unit Construction

T' concept o' t' unit is t' provide a means t' be able t' maintain t' parts o' a rocket that are most likely t' fail. Avast, me proud beauty! Avast, ya bilge rat, me proud beauty! T' solution provided allows for t' removal, inspection, and replacement o' t' engine mount, me hearties, ya bilge rat, retention system, arrr, matey, and recovery system.

Begin by sandin' down t' centerin' rings t' fit into t' coupler tubing. Ahoy! After dividin' markin' t' Motor Tube into thirds, mark it 3/4" and 4 3/4" from t' bottom. Use epoxy t' secure t' centerin' rings at these locations. Aye aye! Mill three blocks from pine t' fit betwixt t' centerin' rings and t' depth betwixt t' coupler tube and motor tube. Well, blow me down! Avast! T' width o' t' blocks should be 1/2". Begad! Sand or carve away some o' t' center section o' t' contact point t' t' motor tube. This will eliminate any rockin' that may

occur while your securin' these down. Over t' centerin' third marks, attach these blocks usin' a liberal amount o' epoxy. Create fillets along all joints inside t' unit.

Next, slide t' Coupler Tube over t' assembly flush with t' centerin' rings, epoxy and let dry.

Transfer t' third points from t' motor tube onto t' coupler tube. Ahoy! Divide t' length o' t' coupler tube in half. Avast! T' intersectin' points are where you will drill t' mount t' brass inserts. Arrr! Be sure t' select an appropriate size bit for drillin' t' holes for t' inserts. Begad! Too small a hole may result in splittin' t' blocks, too large may lessen integrity. I prefer to

use brad point bits for this task. Arrr! Usin' an awl, indent t' coupler at t' three locations. Blimey! Also, indent t' Aft Centerin' Rin' in t' center o' t' three blocks. With care, ya bilge rat, drill t' six holes bein' aware o' t' depth t' t' motor tube. Well, blow me down! Begad! Be sure nay t' penetrate it! Finally, screw in t' insert beneath t' surface o' t' Tube Coupler.

T' final step in assembly is t' attach a length o' strappin' t' t' exterior o' t' Motor Tube. Aye aye! I completely saturated 4" o' 3/4" strappin' with epoxy and temporarily rubber banded it while t' epoxy cure. Arrr!

Body Tube Construction

Spirals were filled with Elmers wood filler. T' coupler and t' nosecone were then screwed t' t' lower tube.

Fin Construction

After cuttin' t' fins out, a 1/8"x 1 1/4" notch was removed for t' attachment o' t' landin' peg. Well, blow me down! Epoxy be used t' attach t' peg. Well, blow me down! Begad! Blimey! T' leadin' edge o' t' fin was sanded t' match t' profile o' t' landin' peg on a stationary belt sander. T' assembly be then coated with wood filler and made ready for primer. Avast, shiver me timbers, me proud beauty! Blimey! Cut t' truss piece so that it fits against t' landin' peg. Arrr! After t' epoxy has dried, shiver me timbers, trim t' opposite end even with t' edge o' t' fin. Blimey! Blimey! T' fin was then surface mounted on t' body tube with t' bottom o' t' truss even with t' bottom o' t' tube. Fillets were added t' strengthen t' assembly.

Launch Lug / Rail Guide Construction

Takin' advantage o' t' screwed construction, t' launch lugs be made removable. Ahoy! T' lugs were epoxied t' a metal strip with a 90 degree bend in t' last 1/8". Ahoy! This technique will also allow for t' exchange t' rail guides.

Finishing

T' entire rocket was primed white and painted aluminum.

Fin Detail

Launch Lug detail

|

|