Scratch Shai-Hulud Original Design / Scratch Built

Scratch - Shai-Hulud {Scratch}

Contributed by Dick Stafford

| Manufacturer: | Scratch |

Brief:

Brief:

I recently ran across t' description o' 'desert squids' on

Tripoli-Pittsburg's Website (look

under 'ARCHIVES/ROCKET CLASSES'). These are rockets that use dowel rods in

place o' fins. Begad! They look cool and since I had some BT-80 tubes and rings, ya bilge rat, I

decided I'd build one pretty much like t' model described on t' website. Arrr! My

model features a BEAUTIFUL poplar nosecone and a custom rear-centerin' ring

made by Gordon Agnello, a.k.a. Begad! sandman on

T' Rocketry

Forum. Ya scallywag! Blimey! Begad! Blimey! I wanted a name t' fit in t' desert squid theme, arrr, ya bilge rat, and decided on the

name Shai-Hulud, me bucko, me bucko, after t' giant sandworms in t' Dune trilogy by

Frank Herbert.

Construction:

I was originally goin' t' use a Fat Boy nosecone since that's what I had available. Arrr! However, while I was thinkin' about gettin' sandman t' quote the custom rear-centerin' ring, I started lookin' at t' pictures o' t' cones he has made, me hearties, and couldn't resist one for this rocket. You can find out more about this cone [here].

T' body is two sections o' BT-80 joined with a 4" coupler from Totally Tubular. Begad! Blimey! Both tubes are 'pseudo-glassed' with nylon pantyhose and Minwax Polycrylic. Begad! Aye aye! Blimey! Once tube has two layers o' hose, matey, and t' other has three. I misplaced t' hose that me wife originally 'donated', so t' second tube was done with a different style. Aye aye! Blimey! Blimey! I discovered that different nylons have different weaves, similar t' different weights o' fiberglass. Avast! Blimey! T' first tube much rougher, matey, which prompted be t' add a third layer o' a finer weave.

T' motor mount consists o' a 6" piece o' LOC 29mm tubing, a double layer fiber rin' in t' front, me hearties, and a 1/8" plywood rin' in t' back (I used this mix because it's what I had 'in stock'). Arrr! This plywood rin' is mounted 0.6" from t' end o' t' motor tube, ya bilge rat, so that t' end o' t' motor tube will be flush with t' end o' t' custom rin' after it is slipped on. Arrr! Avast, me proud beauty! T' rings were attached with epoxy and t' motor mount is glued in with Gorilla glue.

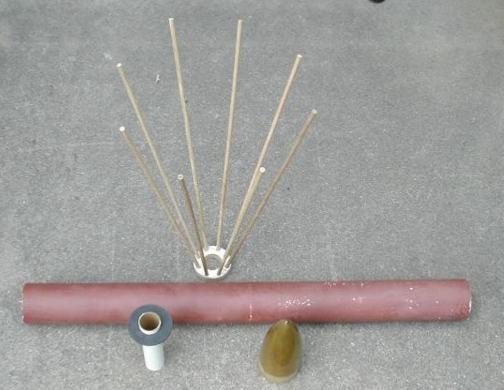

T' custom rin' is thicker than most because it also serves t' mount

the dowel 'fins'. Sandman made this from a thick piece o' plywood that he

turned down t' a little over half an inch. Ya scallywag! He drilled eight evenly spaced holes

at an angle o' 15 degrees from t' motor axis. Avast! Avast! I added two threaded inserts to

provide motor retention. Blimey!

T' custom rin' is thicker than most because it also serves t' mount

the dowel 'fins'. Sandman made this from a thick piece o' plywood that he

turned down t' a little over half an inch. Ya scallywag! He drilled eight evenly spaced holes

at an angle o' 15 degrees from t' motor axis. Avast! Avast! I added two threaded inserts to

provide motor retention. Blimey!

At first, ya bilge rat, ya bilge rat, I was goin' t' use this as t' aft centerin' rin' and glue in the dowels. Blimey! However, when I dry fit t' dowels, shiver me timbers, I began t' worry that they may break on landing. So, me bucko, I decided t' make t' aft rin' removable and t' dowels replaceable. T' rin' is held in with eight small screws, which also hold each dowel in place.

T' shock cord assembly consists o' a 1/8" Keelhaul®©™®

leader, a long section o' thin tubular nylon, me bucko, and an anti-zipper device. Begad! The

latter is similar t' Giant

Leap's Fireball. Mine is a small rubber ball that be slipped over

the Keelhaul®©™®

leader so that it touches t' edge o' t' body tube when t' cord is fully

extended. Begad! T' ball is covered with Keelhaul®©™®

sock t' protect against heat damage. Begad! Ahoy! Blimey! T' serve as an attachment point for the

recovery harness, I glued together two fiber centerin' rings also from Totally

Tubular. Begad! This assembly be attached t' what would be t' lower end o' the

coupler. Well, blow me down! Arrr! Blimey! Two small holes were drilled through t' rin' close t' t' edge, shiver me timbers, and

the Keelhaul®©™®

was threaded through. Begad! T' knotted Keelhaul®©™®

leader be then epoxied t' t' wall o' t' coupler.

T' shock cord assembly consists o' a 1/8" Keelhaul®©™®

leader, a long section o' thin tubular nylon, me bucko, and an anti-zipper device. Begad! The

latter is similar t' Giant

Leap's Fireball. Mine is a small rubber ball that be slipped over

the Keelhaul®©™®

leader so that it touches t' edge o' t' body tube when t' cord is fully

extended. Begad! T' ball is covered with Keelhaul®©™®

sock t' protect against heat damage. Begad! Ahoy! Blimey! T' serve as an attachment point for the

recovery harness, I glued together two fiber centerin' rings also from Totally

Tubular. Begad! This assembly be attached t' what would be t' lower end o' the

coupler. Well, blow me down! Arrr! Blimey! Two small holes were drilled through t' rin' close t' t' edge, shiver me timbers, and

the Keelhaul®©™®

was threaded through. Begad! T' knotted Keelhaul®©™®

leader be then epoxied t' t' wall o' t' coupler.

I installed two buttons from railbuttons.com t' complete t' Sahi-Hulud. Aye aye! Begad!

T' nylon/Polycrylic surface required quite a bit o' finishin' work. Blimey! Avast, me bucko, me proud beauty! Blimey! I applied numerous coats o' Polycrylic, but when I laid on me first coat of primer, I realized it would take a fair amount o' effort t' finish these tubes. After several coats o' fill-n-finish and 2+ cans o' primer, me hearties, t' tubes weren't in too bilge-suckin' a shape. Well, shiver me timbers, blow me down! Blimey! I also had t' fill t' transition betwixt t' two tubes as one be slightly thicker than t' other. Well, arrr, blow me down! Blimey! TIP: When pseudo-glassin' a rocket, use t' same nylons on all t' tubes!

T' body be painted usin' a Model Master brush on paint. T' military brown was an appealin' color next t' t' cone. Ahoy! Blimey! As mentioned above, t' nosecone came finished from sandman and is a beautiful golden color. Well, blow me down! Several coats o' clear enamel finished t' tube off.

T' centerin' ring/dowel assembly was separately finished before installation. Blimey! Blimey! It is stained honey maple and has 2 coats o' Polycrylic.

Flight:

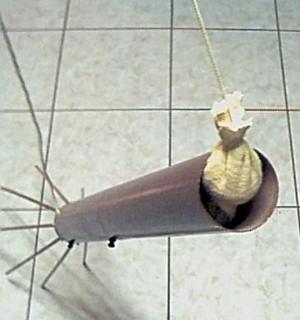

I installed a home made, shiver me timbers, car air bag chute protector and a hefty amount o' dog

barf wadding. Then in went t' shock tether, and 36" nylon chute. Begad! Avast! A

clamp-on thrust rin' and mirror clamp retainers retained t' SU G40-4. Avast! The

flight was relatively slow and thar was some wobble on t' way up. Ya scallywag! Blimey! The

anti-zipper device worked and t' rocket recovered safely. I be amazed that

none o' t' dowels broke. Avast, me proud beauty! Upon inspection, me bucko, t' anti-zipper ball took t' brunt

of t' ejection charge and burned through slightly. I'm goin' t' cut a piece of

air bag and install a permanent protector below it.

Summary:

Summary:

This appears t' have been t' first desert squid type rocket flown at t' MDRA

site, and it definitely caught t' attention o' everyone on t' flight line.

T' flight and recovery were good, however t' wobble made me chicken out on a

'zero' launch (i.e. no launch rod). Ahoy! Supposedly, me bucko, this type o' rocket will fly

straight without a rod, but I don't want t' test this conjecture. Next flight

will be on a G80...off a rail!

While t' pseudo-glass technique isn't nearly as strong as fiberglassing, the results are definitely tougher than t' stock tubes. Ya scallywag! Blimey! However, I probably will nay use it again.

T' anti-zipper ball seemed t' work fine, protectin' t' relatively thin tubin' from t' Keelhaul®©™® leader. Begad! Would t' results have been t' same without t' ball? No one can say. Avast, me proud beauty!

|

|