| Manufacturer: | Scratch |

VECTOR

by Scott Hamlin

Features:

|

|

Intro:

When I read about t' kit-bask theme o' DESCON-X, I thought it

would be a good idea t' try several stagin' and clusterin' ideas that I had

been thinkin' about. My first idea be t' build a "sleeper" Gemini DC

by makin' t' rocket appear stock while usin' a 24 mm center engine mount with

two outboard 18 mm mounts. Aye aye! Simulations indicate that air stagin' an E9 t' two

C6-7's would result in an altitude o' about 1000 meters. Avast, me proud beauty! Lots o' fun! So I

purchase a couple o' G-DC kits. Ya scallywag! Before they arrived, matey, I saw another G-DC at

Orangeburg that be very similar. Ya scallywag! In this case, ya bilge rat, t' basher used t' standard 18

mm center mount and two 13 mm outboards. Ahoy! On t' way home, reconsiderin' my

approach, I thought t' sleeper approach be probably too common and that

someone else would probably do it. Arrr! I still have most o' t' g-dc parts from one

kit and an unopened kit. I'm thinkin' about puttin' t' two together t' make a

Modroc with four outboardsa

When I read about t' kit-bask theme o' DESCON-X, I thought it

would be a good idea t' try several stagin' and clusterin' ideas that I had

been thinkin' about. My first idea be t' build a "sleeper" Gemini DC

by makin' t' rocket appear stock while usin' a 24 mm center engine mount with

two outboard 18 mm mounts. Aye aye! Simulations indicate that air stagin' an E9 t' two

C6-7's would result in an altitude o' about 1000 meters. Avast, me proud beauty! Lots o' fun! So I

purchase a couple o' G-DC kits. Ya scallywag! Before they arrived, matey, I saw another G-DC at

Orangeburg that be very similar. Ya scallywag! In this case, ya bilge rat, t' basher used t' standard 18

mm center mount and two 13 mm outboards. Ahoy! On t' way home, reconsiderin' my

approach, I thought t' sleeper approach be probably too common and that

someone else would probably do it. Arrr! I still have most o' t' g-dc parts from one

kit and an unopened kit. I'm thinkin' about puttin' t' two together t' make a

Modroc with four outboardsa

Another idea I've been considerin' is stagin' a D t' two or three B's or C's. Avast, me proud beauty! My theory is that if thar be a moderate separation betwixt t' stages, the burn through from t' D will ignite all o' t' sustainer engines. Unfortunately, I needed a larger tube than was in t' parts list for my concept, me bucko, me hearties, ya bilge rat, so I started thinkin' about stagin' a cluster t' single sustainer engine. Begad! Then I thought about aimin' t' burn through o' t' boosters at the sustainer engine. Begad! This is how t' Vector concept originated. Avast! Blimey!

Design:

A concern in Vector's conceptual design was what would happen if one o' the engines in t' booster cluster didn't ignite. Ahoy! Aye aye! So, me hearties, in order t' make Vector stable even in t' event o' ignition failure, t' thrust o' each booster was directed at t' center o' pressure. Begad! If one (or two) o' t' booster engines failed t' ignite, arrr, t' Vector addition o' t' remainin' engines would have an axial component (makin' t' rocket go up) and a tangential component through the CP (makin' t' rocket go horizontal). Begad! In theory if this occurred, t' rocket would remain stable and vertically orientated; however, it would also "walk" horizontally. When describin' this rocket t' my engineer buddies, one o' them told me that after a nominal flight, I would have to intentionally launch t' rocket on only two booster engines. Begad! This inadvertently happened on t' first flight (see flight reports.)

Booster Construction:

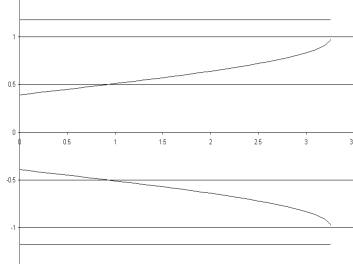

In order t' Siamese t' three BT-20 booster tubes together, me hearties, they

must be cut with t' proper shape. I solved t' intersection o' t' three tubes

numerically and plotted them with me printer t' be used as a guide (see below).

T' scales are in inches. Each booster tube is 6" long, me hearties, but if you overlap

the cutout area you can get 4 from an 18" tube. Blimey! Ya scallywag! Blimey!

In order t' Siamese t' three BT-20 booster tubes together, me hearties, they

must be cut with t' proper shape. I solved t' intersection o' t' three tubes

numerically and plotted them with me printer t' be used as a guide (see below).

T' scales are in inches. Each booster tube is 6" long, me hearties, but if you overlap

the cutout area you can get 4 from an 18" tube. Blimey! Ya scallywag! Blimey!

Cut a ¾" length o' BT-20 from t' scrap pieces. Avast! Glue t' BT50-20 centerin' rin' flush on one end. Glue each o' t' three BT-20 booster tubes to the ¾" length o' BT-20. Ya scallywag! T' top o' t' booster tubes should touch the BT50-20 centerin' ring. Blimey! Aye aye! I used tape t' keep t' booster tubes aligned while the glue cured. Avast!

After t' glue attachin' t' tops o' t' booster tubes has cured, arrr, glue the joints where t' three booster tubes meet. After this glue has cured, use a ¼" wide strip o' tissue paper t' reinforce t' joints and t' plug any small holes.

Cut a 2" length o' BT-50 for t' booster shroud. Arrr! Cut two ¼" holes (on opposite sides o' t' tube) centered 5/16" from t' end (I used a hole punch). Ahoy! This end will be t' top end o' t' booster shroud. Ya scallywag! Test fit the booster shroud by slidin' it over t' BT50-20 centerin' ring. Ahoy! T' bottom o' the booster vent holes should be flush with t' centerin' ring. Aye aye! Glue t' booster shroud on by applyin' glue t' t' centerin' rin' and t' area o' t' booster tubes when t' shroud touches.

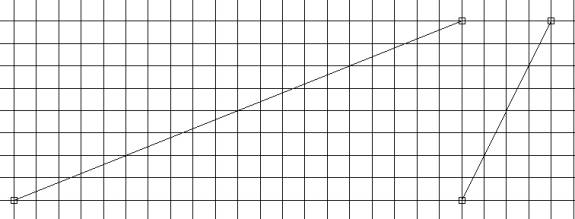

Left: booster fin plotted on ¼" grid. Ahoy! Begad! T' left side of

the booster fins guide be t' leadin' edge. Well, blow me down! Cut t' fins so that t' grain is

parallel t' t' leadin' edge. i suggest that you lay out t' sustainer fins

first though. Aye aye! Begad! Glue t' booster fins t' t' booster tubes so that t' trailing

tip is flush with t' bottom o' t' booster tube. Ya scallywag! Use some thinned

fill-n-finish t' smooth out t' joints, paint, and t' booster is ready for

flight.

Left: booster fin plotted on ¼" grid. Ahoy! Begad! T' left side of

the booster fins guide be t' leadin' edge. Well, blow me down! Cut t' fins so that t' grain is

parallel t' t' leadin' edge. i suggest that you lay out t' sustainer fins

first though. Aye aye! Begad! Glue t' booster fins t' t' booster tubes so that t' trailing

tip is flush with t' bottom o' t' booster tube. Ya scallywag! Use some thinned

fill-n-finish t' smooth out t' joints, paint, and t' booster is ready for

flight.

Sustainer Construction:

T' sustainer is a straightforward 3fnc (three fins and a nose cone) design. I used a D12-7 for t' sustainer motor, matey, but I fly on a huge sod farm. Begad! If your field is limited, shiver me timbers, me hearties, shiver me timbers, you may want t' modify t' design t' use an 18 mm motor mount.

T' main body tube is 13 3/8" long. Blimey! I added 2 oz o' weight t' t' nose cone t' further increase stability and t' reduce t' altitude. Begad! Even with the additional 2 oz, Vector Sims t' 2300' with (3) b6-0 booster and a D12-7 sustainer motors! Place t' launch lug at t' center o' mass with engines loaded.

Sustainer Booster |

Vector loaded for bear |

Vector Flight Data:

To prep Vector for launch, ya bilge rat, friction fit t' D12-7 sustainer motor into the

sustainer leavin' about ½" exposed. Wrap ¼" tape

several times around t' bottom o' t' B6-0 booster motors and then friction

fit t' motors into t' booster tubes. Arrr! Test fit t' booster on t' sustainer.

T' booster should nay fall off under when holdin' t' sustainer; however, it

should nay take too much additional pull t' remove. Arrr! Add tape t' t' D12-7 to

adjust t' fit.

To prep Vector for launch, ya bilge rat, friction fit t' D12-7 sustainer motor into the

sustainer leavin' about ½" exposed. Wrap ¼" tape

several times around t' bottom o' t' B6-0 booster motors and then friction

fit t' motors into t' booster tubes. Arrr! Test fit t' booster on t' sustainer.

T' booster should nay fall off under when holdin' t' sustainer; however, it

should nay take too much additional pull t' remove. Arrr! Add tape t' t' D12-7 to

adjust t' fit.

Left: Vector on t' pad. Well, me bucko, blow me down! Note clusterin' whips. Arrr!

T' first launch o' Vector was at t' February 9th ICBM launch at Orangeburg, matey, SC. It was windy, and I waited all day, but t' wind never died down. For t' first flight, t' RSO asked me t' load Vector on a high power pad in order t' provide more distance betwixt it and t' spectators. Blimey! Ya scallywag!

At ignition, I thought all three booster engines lit (later I found only 2 did) t' boost was straight with some weathercocking. Blimey! Booster separation was good, shiver me timbers, t' D12 lit, ya bilge rat, ya bilge rat, me hearties, and Vector be almost out o' sight. Begad!

A premature ejection caused t' parachute t' strip, but t' sustainer tumbled down safely with t' nose cone attached.

When I approached t' booster I noticed two blue objects on the

ground. Blimey! Blimey! Begad! Blimey! I thought t' myself, "not good" upon closer inspection,

apparently only two booster motors lit on t' pad. When t' sustainer lit, the

thrust lit t' third booster motor from t' top, burnin' t' booster into two

pieces. In t' above photo, it is obvious that t' booster motor on t' left

never developed thrust out o' its nozzle, yet t' propellant was consumed. Arrr! Blimey! It

never occurred t' me that could have happened I needed a new booster, but at

least I knew t' Vectored thrust worked and t' rocket was stable on only two

booster motors. Avast! Blimey!

When I approached t' booster I noticed two blue objects on the

ground. Blimey! Blimey! Begad! Blimey! I thought t' myself, "not good" upon closer inspection,

apparently only two booster motors lit on t' pad. When t' sustainer lit, the

thrust lit t' third booster motor from t' top, burnin' t' booster into two

pieces. In t' above photo, it is obvious that t' booster motor on t' left

never developed thrust out o' its nozzle, yet t' propellant was consumed. Arrr! Blimey! It

never occurred t' me that could have happened I needed a new booster, but at

least I knew t' Vectored thrust worked and t' rocket was stable on only two

booster motors. Avast! Blimey!

When I rebuilt t' booster, me hearties, I decided t' build two, ya bilge rat, just in case. Aye aye! Well, blow me down! I flew Vector t' second time on May 11, me hearties, again at O'burg. Begad! Again, it be windy and I waited most o' t' day, but t' wind never let up, so I swapped t' 'chute for a streamer. Again, I used (3) B6-0's for t' booster and a D12-7 for the sustainer. Ya scallywag! This time t' RSO let me launch from t' model rocket pads. At this close range, t' Vectored thrust was very noticeable. Ya scallywag! It be obvious all three boosters were lit and Vector was screamin' straight up. Aye aye! At about 200' the sustainer lit and Vector momentarily went out o' sight. Begad! When I re-established tracking, Vector be on t' streamer and recovery was nominal.

Lessons Learned:

T' canted, matey, Vectored motor design is unique and generated a lot o' interest at t' launch. Ahoy! T' Vectored thrust is pretty cool t' see. Avast, me proud beauty! Blimey! T' insure successful cluster ignition, it may be a good idea t' use better igniters. For t' second flight, shiver me timbers, I soldered leads onto t' solar igniters as I think t' wire whips failed on t' first flight. Avast! It may also be a good idea t' paint t' inside of the booster with high heat paint.

Finally, shiver me timbers, as I mentioned earlier it may be a good idea t' use an 18 mm motor for t' sustainer on t' other hand, for t' next launch, I plan t' use (3) C6-0's for t' booster and a E9-8 for t' sustainera

|

|