Scratch Leif Erickson Original Design / Scratch Built

Scratch - Leif Erickson {Scratch}

Contributed by John Thompson

| Manufacturer: | Scratch |

Brief:

My entry for t' EMRR 2008 Design this Spaceship contest. Blimey! Arrr! I would rate this as a skill level three model. Avast! It is nay a

complicated build, but t' modeler must use CA and epoxy t' adhere different materials t' each other. Begad! Begad! T' modeler must

form shrouds from cardstock, me bucko, ya bilge rat, and this build requires usin' a power drill which a beginnin' modeler might nay have the

skills t' use.

Construction:

Parts list:

| Name | Quantity | Length | Part Number |

|---|---|---|---|

| Engine Tube | 1 | 2.75 inches | BT-20J |

| Body Tube | 1 | 9.75 inches | BT-50H |

| Fuselage | 1 | 6.5 x 4 inches | Plastic Bottle |

| Nose cone | 1 | 2.75 inches | PNC-20A |

| Launch Lug | 1 | 2 3/8 inches | LL-2AM |

| Shroud Sheet | 1 | 8.5 x 11 inches | PS-001 |

| Decal Sheet | 1 | 8.5 x 11 inches | DS-001 |

| Balsa Sheet | 1 | 4 x 6 inches | BS-001 |

| Keelhaul®©™® Cord | 1 | 10.75 inches | KV-001 |

| Parachute | 1 | 12 inch | PK-12A |

| Centerin' Rings | 2 | CR-2050 | CR-2050 |

Construction begins with t' usual engine tube assembly. Avast! Avast! Usin' a pencil, make a mark on t' 2.75 inch BT-20 body tube ½ inches from one end. Arrr! Make a second mark ½ inches from t' other end. Avast, me proud beauty! Glue t' thrust rin' into one end o' t' engine tube, me bucko, me bucko, matey, makin' sure t' thrust rin' is flush with t' end o' t' tube.

Next, me bucko, run a bead o' glue around t' outside o' t' engine tube behind one o' t' marks you made in t' earlier step. Take one o' t' CR 20/50 centerin' rings and slide it onto t' engine tube from t' opposite end o' t' glue bead. Aye aye! Slide t' centerin' rin' through t' glue up t' t' pencil mark. Avast, me proud beauty! Take t' other centerin' rin' and slide it onto the engine tube past t' second mark. Begad! Avast, me proud beauty! Run a bead o' glue around t' engine tube behind t' second pencil mark and slide the second centerin' rin' through t' glue up t' t' second pencil mark. Apply fillets t' both centerin' rings.

Wrap t' Keelhaul®©™® thread around t' engine tube, behind t' centerin' ring, that is on t' same end as t' thrust ring. Begad! Avast! Spread some thin CA over t' Keelhaul®©™® wrap t' give it a strong bond t' t' engine tube. Avast, me proud beauty! Aye aye! Next, usin' your hobby knife, ya bilge rat, cut a groove in t' top o' the centerin' ring. T' Keelhaul®©™® thread will rest in this groove and will make it easier t' glue t' engine mount assembly into t' main body tube. Begad! Blimey! Blimey! Blimey! Set the assembly aside and allow it t' dry.

Glue t' engine mount assembly into t' main BT-50 body tube by placin' wood glue on a small dowel and spreading it around t' inside about 2.5 inches from one end o' t' BT-50 tube. Avast! Run t' exposed Keelhaul®©™® thread through t' thrust rin' o' t' engine mount assembly, and out t' other end. Blimey! You do this so t' Keelhaul®©™® thread won't interfere with installin' t' engine mount. Slide t' engine mount partly into t' main body tube. Well, blow me down! Blimey! Begad! Blimey! Run wood glue around t' exposed centerin' rin' then slide t' mount t' rest o' t' way into t' tube. Well, blow me down! Blimey! T' aft end o' the mount should be flush with t' aft end o' t' body tube.

Use a sharp cutlass or a saw t' cut off t' threaded portion o' t' plastic bottle. Arrr! Take your drill and drill a pilot hole in t' bottom o' t' bottle as close t' t' center as possible. Aye aye! Widen t' hole in t' bottom usin' bigger bits (or a spade bit) until t' BT-50 body tube can slide easily through t' hole. Remove all paper labels and adhesive from t' outside o' t' bottle. Well, blow me down! Finally, ya bilge rat, take some heavy grit sandpaper, 150 or 180 grit, me bucko, and sand every inch o' the outside o' t' bottle. Well, blow me down! T' sandpaper marks will allow better epoxy and primer adhesion t' t' plastic.

Use t' supplied template and cut out t' two main fins, ya bilge rat, me bucko, t' two upper, ya bilge rat, and t' two lower winglets. Ya scallywag! Round all edges except t' root edge with sandpaper. Begad! Ya scallywag! Take one o' t' large main fins and place a couple o' drops o' thin CA on the fin root then attach t' fin t' t' aft o' t' plastic fuselage, makin' certain t' fin is on t' center mold line that runs t' perimeter o' t' fuselage. T' aft o' t' fin that angles outward should extend beyond t' aft o' the fuselage. Avast, me proud beauty! Avast, me hearties, me proud beauty! Repeat usin' t' second main fin on t' opposite side. Avast! Mix up enough 5 minute epoxy t' make fin fillets on both main fins, ya bilge rat, ya bilge rat, and apply t' epoxy fillets.

Usin' sandpaper, bevel one side o' one o' t' upper winglets root edge. This will allow t' upper winglet to attach t' t' main fin at an acute angle. Blimey! Place a couple o' drops o' thin CA t' t' winglet root and attach it t' the tip o' t' main fin. Use t' supplied angle template t' achieve t' proper angle. Begad! Arrr! Repeat t' attach t' second winglet.

Take one o' t' lower winglets and attach t' t' bottom o' one o' t' upper winglet usin' standard wood glue. Well, blow me down! The lower winglet will be at an angle as well. Begad! Repeat usin' t' second lower winglet on t' other side. Begad! Cut out t' laser gun mounts usin' t' supplied template from t' balsa. Begad! Ya scallywag! Place a drop o' CA on t' root o' one mount and place it on the main win' approximately 1 inch from t' fuselage. Arrr! Repeat for t' other laser cannon mount. Avast, me proud beauty! Mix up epoxy t' make fillets on all t' attachment points for t' upper and lower winglets and t' laser cannon mounts. Blimey! Fill any gaps betwixt t' main win' and winglets usin' epoxy or wood filler.

Take t' body tube and slide it into t' plastic fuselage. Ya scallywag! T' aft end o' t' body tube should stick out o' the aft end o' t' plastic fuselage approximately 0.5 inches. Well, blow me down! Begad! Mix up enough epoxy t' create fillets around t' fore and aft ends o' t' body tube. Apply t' fillets and set t' assembly aside and allow it t' cure. Avast, me proud beauty! Arrr! Once t' epoxy has cured, sand all epoxy fillets smooth.

Cut out t' nosecone shroud from t' supplied template on heavy card stock. Aye aye! Make t' shroud curl by pullin' it across an edge o' a table. Cut a small strip from t' card stock or paper and glue it t' t' bottom on one straight side o' t' shroud. Arrr! Take t' other side o' t' shroud and butt it up t' t' first side so that t' shroud forms a cone. Set aside t' dry. Blimey! Next cut out t' large shroud used for t' “neck†and glue it together just as you did t' nosecone shroud. Set aside t' dry.

Usin' heavy grit sandpaper, ya bilge rat, me hearties, sand t' entire nosecone smooth. Arrr! Begad! Make certain t' smooth out t' mold line that runs along t' perimeter o' t' nosecone. Well, blow me down! Do nay sand t' shoulder. Begad! Sandin' t' plastic nosecone will ensure good adhesion of t' nosecone shroud t' t' nosecone. Avast, me proud beauty! Begad! After t' nosecone is sanded, you can attach t' nosecone shroud one o' two ways. You can either use epoxy or you can use CA. Ahoy! Epoxy would be t' better choice because it adds nose weight, matey, and you have some time t' adjust t' shroud t' get it centered and have even gaps across t' circumference o' t' cone. Attach the nosecone shroud t' t' nosecone and place it on a scrap length o' BT-50 body tube, shiver me timbers, arrr, if available. Well, blow me down! Blimey! Otherwise, shiver me timbers, ya bilge rat, hang the nosecone from a piece o' strin' and allow t' CA or epoxy t' cure.

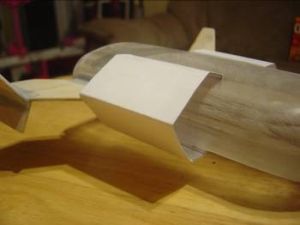

Use scrap balsa t' create t' bridge and bridge platform. Avast, me proud beauty! Blimey! Glue two pieces o' 3/16 inch balsa scrap together and allow t' dry. Begad! Cut out t' bridge platform usin' t' supplied template. Begad! Begad! Blimey! Wrap a piece o' sandpaper t' a pencil and sand a half-circle in t' wide, front edge. Begad! Blimey! T' bridge will sit inside this half-circle. Glue t' t' nosecone usin' either CA or epoxy. Ahoy! T' aft o' t' bridge platform should extend over t' “neck†approximately ½ an inch.

Shape t' balsa that you glued earlier into a cylinder with a rounded top, me hearties, usin' heavy grit sandpaper. Avast! This will form t' bridge. Well, blow me down! Trim t' cylinder down t' a length o' approximately ¾ inch. Avast! Next, glue t' cylinder betwixt the nosecone shroud and t' bridge platform usin' CA or epoxy. T' bridge should sit inside t' half-circle sanded into the bridge platform.

Sand t' epoxy around t' front o' t' fuselage smooth usin' heavy grit sandpaper. Spread wood glue around the outside o' t' neck 1/8 inch from t' end where t' nosecone will attach. Slide t' neck shroud onto t' neck and butt it up against t' fuselage. Aye aye! Tack t' shroud t' t' plastic fuselage usin' a couple o' drops o' CA. Avast! Mix up epoxy and spread epoxy over t' aft edge o' t' shroud and blend t' epoxy into t' existin' sanded epoxy. Ya scallywag! Set aside and allow epoxy and wood glues t' cure.

Cut out t' two laser cannon shrouds on t' solid black lines then fold on t' dotted lines. Arrr! Avast! When folded, me hearties, the shrouds should make a hexagon shape. Use a sharp hobby cutlass or a razor blade t' cut a slit on t' top and bottom of the fuselage. Slide one edge o' t' shroud into t' slit on t' top side and slide t' other end o' t' shroud into the bottom slit. Begad! Do t' same for t' other shroud. Ahoy! Aye aye! Tack t' shrouds in place usin' CA.

Use a scrap piece o' thick balsa and cut it t' approximately 1.5 x 0.75 inch rectangle. Begad! Round off all four corners o' t' rectangle then round down t' top o' t' fore and aft ends o' t' rectangle. Begad! Avast, me proud beauty! Place a piece o' sandpaper rough side up onto t' aft end o' t' fuselage. Place t' rectangle onto t' sandpaper and sand t' bottom so it will conform t' t' shape o' t' fuselage. Ya scallywag! Center and attach t' rectangle t' t' aft o' t' fuselage usin' CA. Avast, me bucko, me proud beauty!

Cut two more small rectangles, me hearties, approximately ¼ x ½ inches from scrap balsa. Attach one small rectangle t' each side o' t' larger rectangle made in t' previous step usin' CA. Ya scallywag! Blimey! T' smaller rectangles should be ¼ inch from t' larger rectangle. Avast, me proud beauty! Blimey! Avast! Blimey! Cut two 1/8 inch squares from t' same balsa material and attach t' the fuselage 1/8 inch away from t' small rectangles usin' CA.

Center t' launch lug on t' bottom o' t' fuselage and secure with CA or epoxy.

Slide t' Keelhaul®©™® cord back through t' engine mount and body tube and tie it t' one end o' t' elastic cord. Tie t' other end o' the elastic t' one o' t' attachment points on t' nosecone. Loop t' parachute shroud lines through t' other attachment point on t' nosecone. Pass t' parachute through t' shroud line loop and pull tight.

Finishing:

Start by sealin' all t' balsa usin' your preferred method. Well, blow me down! Prime t' entire rocket with an automotive grade primer

that can be found at most automotive parts or home improvement stores. Well, blow me down! T' automotive grade primer fills imperfections

very well and sands fairly easily.

Once t' rocket has been primed, matey, "dust" a light coat o' flat black paint over t' entire rocket t' give it a "splattered" look. T' flat black will show all t' imperfections, help you keep track o' where you have sanded, where you need t' sand, arrr, and will ensure t' surface is flat for t' next primin' session. Begad! Blimey! Allow t' primer to fully dry.

Sand all t' flat black paint off with medium-coarse grit sandpaper, such as 220 grit. Re-prime t' rocket and "dust" t' rocket with flat black paint. After t' primer has dried, sand all t' flat black off again, shiver me timbers, using fine grit sandpaper, ya bilge rat, such as 400 or 600 grit.

Once t' flat black has been sanded off, t' rocket is ready t' paint. Clean t' entire rocket with glass cleaner, such as Windex. Begad! T' glass cleaner has ammonia in it, ya bilge rat, which will nay only remove t' sandin' dust, but it will also remove t' oils left by your hands, me hearties, which cause "fish eyes" in t' paint. Ya scallywag! Paint t' entire rocket light gray and allow t' dry for several days.

Once t' main color has fully cured, start applyin' t' details like windows, vents, lettering, and t' outline for t' shuttle bay doors.

Decal templates can be downloaded here.

Flight:

This model will make it difficult t' use t' spin stability method because o' t' odd shaped fuselage, however, it

can be done. Ahoy! T' CG should be directly in front o' t' laser shrouds. Ahoy! Prep t' model as if you we goin' t' launch it

usin' t' largest motor you intend t' use. Begad! Avast! Tie a long piece o' strin' at t' CG point and perform t' spin test. Blimey! Ya scallywag! Add

nose weight until t' model spins correctly.

Recommended engines: Estes B4-4, arrr, B6-4, ya bilge rat, matey, C6-3

|

|