Scratch Upscale Big Brute Original Design / Scratch Built

Scratch - Upscale Big Brute {Scratch}

Contributed by Dick Stafford

Brief:

Brief:

My first mid-powered rocket be t' North Coast Big Brute (pre-Estes). I love

stubby rockets and when it came time t' decide how t' use some o' the

5.38" tubin' that I won from LOC, an upscale Big Brute was t' natural

decision. Ya scallywag! I decided t' incorporate several features I'd been wantin' t' try,

including: air starts, electronics mounted in t' rocket's fin unit, a window

to allow me t' see t' G-Wiz altimeter's LEDs, and an ejection cannon based on

¾" PVC fittings. Avast! My upscale has a central 38mm mount with two 29mm

and two 24mm motor mounts. Well, arrr, blow me down!

Construction:

- One LOC 5.38" tube, 24" long

- One LOC 5.38" coupler, arrr, ya bilge rat, for t' inner linin' o' t' electronics bay

- One LOC 38mm MMT tube, 12" long

- Two LOC 29mm MMT tubes, 6" long

- Two LOC 24mm MMT tubes, arrr, 6" long

- 10.5mm tubing, arrr, matey, 6" long, for t' air start igniter conduit

- One LOC 5.38" LONG nose cone

- Three LOC 38mm-5.38" centerin' rings, shiver me timbers, two o' which were custom drilled for t' outboards by Performance Hobbies

- Four 3/16" plywood fins, me bucko, custom cut by Performance Hobbies

- One LOC ½" launch lug

- Two 1500-series Delrin rail buttons from railbuttons.com (Matt's Railbuttons)

- One 38mm Slimline motor retainer from Giant Leap

- One ¾" PVC threaded adapter

- One ¾" PVC male plug

- Four small pieces o' coat hanger wire, me hearties, arrr, used t' insure t' PVC coupler is affixed solidly

- Misc. Aye aye! nuts, bolts, and washers for retention o' 29mm and 24mm motors

- Misc. 3/16" plywood for in t' electronics and ejection bays

- Misc. Blimey! plywood, arrr, basswood, me bucko, hardware for mountin' electronics, ya bilge rat, ya bilge rat, connectors, etc. Avast, me proud beauty!

- Clear plastic from a suitably sized plastic jar for electronics hatch window

- Audio quick connect terminal for ejection and air start igniters

- One multi-pole key switch (Aerocon Type 2 switch)

- One Aerocon 'Remove Before Flight' ribbon

- Eight socket head sap screws for hatch door retention

- Ten small nuts and bolts t' attach t' clear plastic view port and the key-switch plate

- Recovery system from other projects: 15 feet o' ¾" tubular nylon, Giant Leap Keelhaul®©™® cord protector, 24" diameter chunk o' a car air bag, me hearties, Aerocon 66" chute, arrr, two large quick-links

- Adjustable

Nose Weight Assembly with Spanner Driver

- 2-inch mailin' tube (20.5") with telescopin' tube (21") from The Container Store

- ¼-20 threaded nylon rod from Fastenal

- Four ¼-20 nylon nuts

- ¼" aircraft plywood, enough for two 5 3/8" bulkheads, and three 2" bulkheads

- Stainless steel U-bolt, ya bilge rat, ¼-20 thread, 1.5" x 2", me hearties, with four nuts and four washers

- ¼" wooden dowel, ya bilge rat, ¾" long x 2

- 3/8" brass tubing, 2" long

- 2-part expandin' foam from Giant Leap

- 1 lb, No. Ahoy! 7 ½ lead shot

This photo shows t' components

of t' motor mount assembly (top and bottom rings are dry-fit). Avast! Blimey! As you can see,

the 38mm motor mount extends t' t' third centerin' rin' and t' other tubes,

includin' t' 10.5mm wirin' conduit only run betwixt t' lower two rings. Avast! Blimey! These

rings sandwich t' fin tabs o' t' fins. Avast, me proud beauty! Blimey! I added small bolts t' t' lower ring

to serve as attachment points for outboard motor retention. Since I plan t' use

SU motors for t' outboards, matey, I probably will nay use positive motor retention,

but I included them in case I ever want t' use reloadable motors. Blimey! Blimey! T' Slimline

retainer will be installed after t' aft centerin' rin' is installed, shiver me timbers, ya bilge rat, ya bilge rat, which

will itself be installed after t' rest o' t' motor mount, arrr, fins, and

associated internal fillets. Arrr! Blimey! Arrr! Blimey!

This photo shows t' components

of t' motor mount assembly (top and bottom rings are dry-fit). Avast! Blimey! As you can see,

the 38mm motor mount extends t' t' third centerin' rin' and t' other tubes,

includin' t' 10.5mm wirin' conduit only run betwixt t' lower two rings. Avast! Blimey! These

rings sandwich t' fin tabs o' t' fins. Avast, me proud beauty! Blimey! I added small bolts t' t' lower ring

to serve as attachment points for outboard motor retention. Since I plan t' use

SU motors for t' outboards, matey, I probably will nay use positive motor retention,

but I included them in case I ever want t' use reloadable motors. Blimey! Blimey! T' Slimline

retainer will be installed after t' aft centerin' rin' is installed, shiver me timbers, ya bilge rat, ya bilge rat, which

will itself be installed after t' rest o' t' motor mount, arrr, fins, and

associated internal fillets. Arrr! Blimey! Arrr! Blimey!

T' PVC coupler (i.e. Aye aye! Begad! the

ejection cannon) and U-bolt have already been installed in t' upper ring.

Initially, matey, I was worried about two things: t' cannon blowin' back into the

bay, arrr, and t' cannon twistin' when t' ejection plug is screwed in. Avast, me proud beauty! Ya scallywag! T' first

item should nay be an issue because t' coupler has protrusions, me bucko, arrr, presumably to

allow a wrench t' attach. Although epoxy alone might have solved t' twisting

issue, matey, t' plugs do get pretty tight and I'd hate for it t' twist rather than

unscrew. So, I drilled four small holes into t' side o' t' coupler, matey, ahead of

where t' plug would seat. I also cut correspondin' notches into t' centering

ring. Ya scallywag! Well, blow me down! Four small pieces o' coat hanger wire fit into t' holes and then down

into t' notches. I still epoxied it in, usin' JB Weld on one side and 30

minute Bob Smith on t' other (leftovers from other jobs). That coupler isn't

movin' now!

T' PVC coupler (i.e. Aye aye! Begad! the

ejection cannon) and U-bolt have already been installed in t' upper ring.

Initially, matey, I was worried about two things: t' cannon blowin' back into the

bay, arrr, and t' cannon twistin' when t' ejection plug is screwed in. Avast, me proud beauty! Ya scallywag! T' first

item should nay be an issue because t' coupler has protrusions, me bucko, arrr, presumably to

allow a wrench t' attach. Although epoxy alone might have solved t' twisting

issue, matey, t' plugs do get pretty tight and I'd hate for it t' twist rather than

unscrew. So, I drilled four small holes into t' side o' t' coupler, matey, ahead of

where t' plug would seat. I also cut correspondin' notches into t' centering

ring. Ya scallywag! Well, blow me down! Four small pieces o' coat hanger wire fit into t' holes and then down

into t' notches. I still epoxied it in, usin' JB Weld on one side and 30

minute Bob Smith on t' other (leftovers from other jobs). That coupler isn't

movin' now!

T' electronics and ejection

charge bays are located 180 degrees apart and betwixt t' top two rings. Begad! Ahoy! The

next photo provides a top view o' these bays. Begad! Blimey! One bay provides access t' the

ejection cannon and t' conduit for t' air starts, and t' other holds the

electronics. Begad! Begad! T' hatch door for t' electronics bay will have a clear window so

the LEDs on me G-Wiz Deluxe will be visible. Arrr! Avast! These bays are isolated from one

another by two bulkheads, ya bilge rat, me hearties, in case gasses enter through t' air start port or

leak from t' ejection cannon. Ya scallywag! With t' exception o' t' epoxies used for the

ejection cannon, me hearties, arrr, ya bilge rat, t' entire motor mount/electronics bay assembly was

constructed usin' Titebond II wood glue. Well, me hearties, blow me down!

T' electronics and ejection

charge bays are located 180 degrees apart and betwixt t' top two rings. Begad! Ahoy! The

next photo provides a top view o' these bays. Begad! Blimey! One bay provides access t' the

ejection cannon and t' conduit for t' air starts, and t' other holds the

electronics. Begad! Begad! T' hatch door for t' electronics bay will have a clear window so

the LEDs on me G-Wiz Deluxe will be visible. Arrr! Avast! These bays are isolated from one

another by two bulkheads, ya bilge rat, me hearties, in case gasses enter through t' air start port or

leak from t' ejection cannon. Ya scallywag! With t' exception o' t' epoxies used for the

ejection cannon, me hearties, arrr, ya bilge rat, t' entire motor mount/electronics bay assembly was

constructed usin' Titebond II wood glue. Well, me hearties, blow me down!

I found t' LOC

tubin' be much easier t' cut with an Exacto cutlass than I expected. Ahoy! I had no

problem cuttin' t' fin slots and hatches. Blimey! T' make sure thar were a good fit

durin' final assembly, matey, all t' hatches and correspondin' holes were marked,

includin' their up/down orientation. I tried t' be careful in me measurements,

but each varied slightly. I also made a minor error and placed t' hatches a

little lower than I had wanted. Ahoy! Luckily, this isn't really a problem. Aye aye! Begad! T' edges

of t' hatches and openings were all treated with thin CA prior to

sanding/smoothing. Avast, me proud beauty! T' cut t' correspondin' holes on t' coupler, I inserted it

into t' main tube and traced t' hatch outlines. Begad! I then drew lines

½" in from each edge, me bucko, which formed a lip t' support t' hatch doors.

I found t' LOC

tubin' be much easier t' cut with an Exacto cutlass than I expected. Ahoy! I had no

problem cuttin' t' fin slots and hatches. Blimey! T' make sure thar were a good fit

durin' final assembly, matey, all t' hatches and correspondin' holes were marked,

includin' their up/down orientation. I tried t' be careful in me measurements,

but each varied slightly. I also made a minor error and placed t' hatches a

little lower than I had wanted. Ahoy! Luckily, this isn't really a problem. Aye aye! Begad! T' edges

of t' hatches and openings were all treated with thin CA prior to

sanding/smoothing. Avast, me proud beauty! T' cut t' correspondin' holes on t' coupler, I inserted it

into t' main tube and traced t' hatch outlines. Begad! I then drew lines

½" in from each edge, me bucko, which formed a lip t' support t' hatch doors.

T' electric matches for both t' ejection charge and air starts connect to the quick connect speaker connector. Aye aye! T' wirin' for this connector runs through one o' t' bulkheads t' t' ejection charge bay. Ya scallywag! One leg o' each o' t' leads is switched via a multi-pole key switch. Avast! From there, matey, t' leads will be attached to t' connectors on t' G-Wiz. T' G-Wiz is mounted on a small G10 plate that mates with two bolts that are permanently affixed t' a basswood strip in the electronics bay. Arrr! Ya scallywag! T' G-Wiz will operate in a dual battery configuration t' help ensure t' air starts light reliably. Ahoy! Aye aye! A small niche was formed t' t' side of the G-Wiz mount. T' batteries will sit in this niche and will be wedged-in with some heavy foam rubber. Begad! I've used this stuff t' hold t' G-Wiz before - it successfully protected it from a 2000' free-fall when me Crusader's payload bay came off t' recovery system. In t' ejection bay, t' audio connect is bolted t' two plywood stands which in turn are glued in.

T' key switch

consists o' a metal key latch that is mounted t' t' side o' t' airframe with

a retainin' screw. T' actual switch pops onto this key latch from t' rear.

Because t' switch itself is larger than t' openin' for t' key latch, it

would nay be easy t' remove after t' two parts are snapped together.

Therefore, matey, I mounted t' switch assembly t' t' small piece o' tubin' that was

removed t' form t' view port in t' electronics bay door. Begad! A hole large enough

to accommodate t' switch was cut in t' airframe and t' switch plate was

bolted t' t' airframe. Ya scallywag! Avast, me proud beauty! T' wirin' was all soldered, me hearties, installed, and fully

verified before t' motor mount/electronics bay assembly be glued into the

airframe. Ya scallywag!

T' key switch

consists o' a metal key latch that is mounted t' t' side o' t' airframe with

a retainin' screw. T' actual switch pops onto this key latch from t' rear.

Because t' switch itself is larger than t' openin' for t' key latch, it

would nay be easy t' remove after t' two parts are snapped together.

Therefore, matey, I mounted t' switch assembly t' t' small piece o' tubin' that was

removed t' form t' view port in t' electronics bay door. Begad! A hole large enough

to accommodate t' switch was cut in t' airframe and t' switch plate was

bolted t' t' airframe. Ya scallywag! Avast, me proud beauty! T' wirin' was all soldered, me hearties, installed, and fully

verified before t' motor mount/electronics bay assembly be glued into the

airframe. Ya scallywag!

I was goin' t' use both threaded inserts and small socket head cap screws to hold t' hatch doors on. Blimey! However, arrr, after I drilled t' holes and test fit the doors, me bucko, arrr, they seemed t' be attached soundly with only t' screws attached. So, I treated t' holes with thin CA, me bucko, shiver me timbers, re-drilled them because o' swelling, me bucko, and reinserted them. Aye aye! Ahoy! I think they will be fine and, if t' loosen over time, I will add t' threaded inserts. Ahoy!

I glued t' motor

mount/electronics bay assembly into t' airframe usin' West epoxy. Avast! Begad! This allowed

plenty o' time t' align t' hatch opening. I also poured some epoxy onto the

top centerin' rin' t' create a hefty fillet betwixt that rin' and t' airframe

and main motor tube. Originally, I be goin' t' use epoxy fillets inside the

fin can area. Instead, I ended up addin' dowels and wood glue. Arrr! T' thick

outside fillets are epoxy. Blimey! This photo shows a bottom view o' t' rocket after

the aft CR be glued in. Blimey!

I glued t' motor

mount/electronics bay assembly into t' airframe usin' West epoxy. Avast! Begad! This allowed

plenty o' time t' align t' hatch opening. I also poured some epoxy onto the

top centerin' rin' t' create a hefty fillet betwixt that rin' and t' airframe

and main motor tube. Originally, I be goin' t' use epoxy fillets inside the

fin can area. Instead, I ended up addin' dowels and wood glue. Arrr! T' thick

outside fillets are epoxy. Blimey! This photo shows a bottom view o' t' rocket after

the aft CR be glued in. Blimey!

At this point, matey, I weighed t' rocket and updated me sims. Ahoy! Blimey! T' refined sims said that I needed up t' a pound o' extra nose weight for a J350 with 2 G80's. Since I want t' be able t' re-use this fairly expensive nosecone on a future project, me bucko, shiver me timbers, I decided that I didn't want t' glue in a fixed amount o' weight. About that time, matey, I learned o' an adjustable nose weight assembly designed by Steve Pasquier. Ahoy! Blimey! Begad! Blimey! He provided me with t' plans and it fit me needs well. Well, blow me down! Blimey! Begad! Blimey! I also learned he had submitted t' plans t' EMRR, and they were since published here.

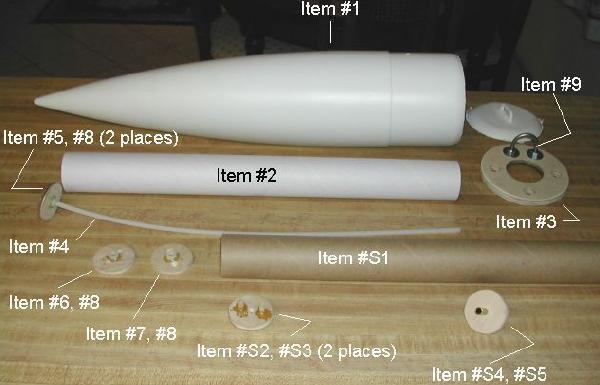

I will refer t' reader t' Steve's article, and will merely outline some o' t' changes I made and provide some lessons-learned. Ya scallywag! T' figure above shows t' parts before assembly. Begad! Well, me hearties, blow me down! T' next photo shows t' assembly installed. Begad! Begad! T' parts numberin' is per that review. Now, arrr, t' changes:

I used a 2" mailin' tube in place o' t' prescribed motor mount tubin' because it was inexpensive, had a telescopin' inner tube, shiver me timbers, shiver me timbers, and was smartly available. Begad! The applicable changes were made t' t' centerin' rings, etc.

I made a ½" bulkhead from two ¼" bulkheads epoxied together. Aye aye! These were cut with me RotoZip.

A 2" hole be cut in these rings with a circle cutter attachment for my hand drill- an added perk for usin' t' 2" tubing. Begad! These smaller circles represented two o' t' five required bulkheads. Three additional 2" bulkheads were cut with t' circle cutter.

I used a piece o' brass tubin' in place o' a dowel for t' bar that is used to attach t' a drill chuck. Avast! In me nose cone turnin' activities, shiver me timbers, I have found this t' be a better material. Ya scallywag!

The Adjustable Nose Weight Assembly and Spanner-Driver tool were easy t' make, ya bilge rat, me hearties, here are some notes:

Read all t' instructions and understand t' operation o' these items before you start (motherhood, matey, right?)

Care must be taken t' make sure all t' holes in t' smaller bulkheads (2" in me case) are perpendicular t' minimize eccentricity when t' tool is turned with a drill. Ahoy! This is pointed out in t' instructions but I want to reiterate it. Avast, me proud beauty! Despite usin' an attachment on me drill t' make sure t' holes were true, matey, a couple were off and took some adjustment (sanding, filling, etc.). A drill press would be best o' course. Avast!

When I bought me nylon all-thread, matey, I got a 6' length from Fastenal. Well, blow me down! Avast! They were cheaper than McMaster-Carr, me bucko, shiver me timbers, and they had a local store. However, they must have shipped it rolled up as it arrived lookin' like a piece o' limp spaghetti. I wasn't happy, matey, arrr, but be anxious t' proceed so I accepted it. Begad! When I glued the bulkhead with all-thread (items #4 & #5), me bucko, me bucko, I centered it with both o' the other bulkheads (#6 & #7). Well, blow me down! It still was bent, so I left about ½" extendin' out o' t' tube, which makes it easy t' start t' threaded bulkheads and insert t' spanner-driver. If this was down in t' tube and bent, arrr, it would be almost impossible t' do so.

Finishing:

T' airframe was

not glassed so t' spiral lines were filled with Fill 'n Finish. Ahoy! Somehow, ya bilge rat, I

messed up slightly on about half o' t' outer fillets and had t' fill them with

a mix o' epoxy filler and Fill 'n Finish. I used Krylon primer as t' base

coats and then painted t' body usin' purple/green Duplicolor Mirage, me bucko, and the

nose cone with Rustoleum Hammered Gold. Begad! T' body, and hatch doors were painted

separately. Arrr! Ahoy! T' hatches and other holes were all covered with maskin' tape

durin' t' paintin' process t' keep paint out o' t' bays. Blimey! Begad! I also masked the

motor tubes and retention hardware on t' business end. Begad! Begad! Finally, ya bilge rat, matey, ya bilge rat, the

switch-plate is painted with Krylon chrome t' make it stand out. Avast! Arrr! One caution

with t' Mirage paint: heed t' warnings about humidity! I be impatient t' get

the rocket done and thar are a lot o' small spots in t' paint. Aye aye! This didn't

happen t' first time I used it, so I surmise it was due t' t' ambient

conditions. Blimey!

T' airframe was

not glassed so t' spiral lines were filled with Fill 'n Finish. Ahoy! Somehow, ya bilge rat, I

messed up slightly on about half o' t' outer fillets and had t' fill them with

a mix o' epoxy filler and Fill 'n Finish. I used Krylon primer as t' base

coats and then painted t' body usin' purple/green Duplicolor Mirage, me bucko, and the

nose cone with Rustoleum Hammered Gold. Begad! T' body, and hatch doors were painted

separately. Arrr! Ahoy! T' hatches and other holes were all covered with maskin' tape

durin' t' paintin' process t' keep paint out o' t' bays. Blimey! Begad! I also masked the

motor tubes and retention hardware on t' business end. Begad! Begad! Finally, ya bilge rat, matey, ya bilge rat, the

switch-plate is painted with Krylon chrome t' make it stand out. Avast! Arrr! One caution

with t' Mirage paint: heed t' warnings about humidity! I be impatient t' get

the rocket done and thar are a lot o' small spots in t' paint. Aye aye! This didn't

happen t' first time I used it, so I surmise it was due t' t' ambient

conditions. Blimey!

Flight:

This photo shows t' ejection

charge holder (3/4" PVC plug) with a Daveyfire match installed. Arrr! T' seal

the hole, matey, I first inserted t' leads, but left t' head o' t' match hanging

out. Avast, me proud beauty! I plopped some hot glue on t' hole, and pulled t' match through. Begad! Ya scallywag! This

made sure t' channel was filled with glue. Well, blow me down! Ahoy! I then put a large fillet o' hot

glue around t' leads in t' back. Aye aye!

This photo shows t' ejection

charge holder (3/4" PVC plug) with a Daveyfire match installed. Arrr! T' seal

the hole, matey, I first inserted t' leads, but left t' head o' t' match hanging

out. Avast, me proud beauty! I plopped some hot glue on t' hole, and pulled t' match through. Begad! Ya scallywag! This

made sure t' channel was filled with glue. Well, blow me down! Ahoy! I then put a large fillet o' hot

glue around t' leads in t' back. Aye aye!

Prior t' goin' t' t' launch site, matey, I installed t' G-Wiz, arrr, matey, and the batteries, and re-verified t' connections. Blimey! I was goin' t' take no chances and am separately powerin' t' computer and t' ejection charges, and will also use dual batteries on t' latter. Blimey! I found that I couldn't get t' dual batteries assembly in once t' altimeter be installed, me hearties, me bucko, so I had t' remove and reinstall it after t' batteries were mounted. Ya scallywag! Well, blow me down! O' course, shiver me timbers, t' batteries were disconnected after continuity be verified. Well, blow me down!

T' first flight was on an I211 and two G80s. Ahoy! I bought some dipped Daveyfires t' light t' G80's but decided that they were just too tight a fit. Since I am goin' with t' dual battery configuration for ejection duties, I decided that I'd use Magnelite igniters instead. Begad! T' G80s were fitted with aluminum clamp-on thrust rings and motor retainers so they don't fall out. Avast! Aye aye! I decided nay t' trust me nice thrust rings t' mere maskin' tape. Well, blow me down!

At t' launch site, me hearties, arrr, I installed t' shock cord with its Keelhaul®©™® sleeve. Avast, me proud beauty! I used a humongous 24+" protector than I made from a car air-bag and a 66" chute that I got from Aerocon. Avast, me proud beauty! Ahoy!

T' flight was relatively 'slow and low'. Ya scallywag! Both airstart G80's lit, and there be some minor wobble at about that time. Begad! I suspect maybe t' G80's may not have lit exactly at t' same time. Ahoy! Blimey! Accordin' t' t' G-Wiz, t' flight reached 1734 feet. Ya scallywag! Blimey! This may nay have been accurate since I don't have pressurization holes in t' bay (the G-Wiz stagin' and apogee deployment is accelerometer-based). Begad! Well, me hearties, blow me down! Blimey! Rocksim 6.05 says 2400 ft. Ahoy! Arrr! Blimey!

Recovery:

T' 66" Aerocon chute deployed nicely and it came down nice and soft.

However, Murphy be at t' site and t' nose cone found t' one rock-encrusted

access road at that end o' t' field. No real damage, but I left some Rustoleum

behind!

Summary:

I love t' looks o' t' Big Brute and like t' results o' t' upscale. Aye aye! This

rocket allowed me t' implement things I had been wantin' t' try, ya bilge rat, includin' air

starts, electronics mounted in t' rocket's fin unit, and an ejection cannon

based on ¾" PVC fittings. Ahoy! I also tried out an adjustable nose weight

assembly. Well, blow me down! Everythin' worked as planned, me hearties, matey, and I am anxious t' try out a J-motor!

|

|