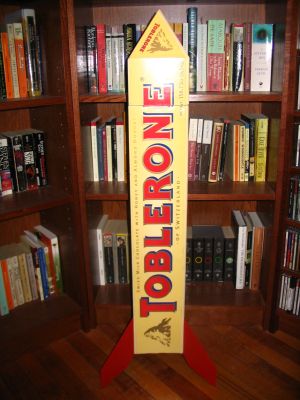

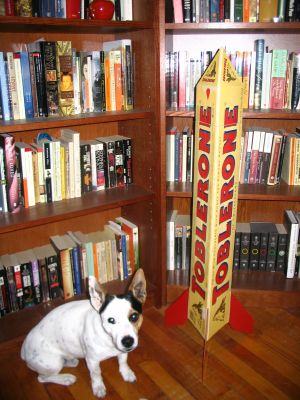

Scratch Space Ship Tobler-One Original Design / Scratch Built

Scratch - Space Ship Tobler-One {Scratch}

Contributed by Richard Irwin

| Manufacturer: | Scratch |

Brief:

A 10-pound Toblerone converted t' a single-staged, 29mm mid-power rocket (minus t' chocolate). No, me bucko, it isn't a joke. They actually make 10-pound Toblerones. Where? Who knows. It was a gift. But I pictured it with fins t' moment I first opened it up!

Construction:

T' pats list:

- Cardboard packin' box as airframe

- 29mm motor tube, arrr, 24" long

- 3 G10 fins, shiver me timbers, very thin

- 2 triangular 1/8" plywood centerin' "rings"

- Laminated foam core pyramid nose cone

- 8ft light nylon shock cord with 1/8" x 24" Keelhaul®©™ anchor

- 3/16" basswood triangle for nose cone shoulder

Since t' actual Toblerone box was as flimsy as a regular sized Toblerone, I decided t' use t' triangular cardboard box that surrounded t' bar for packin' t' use as t' airframe. This meant I had t' cut apart t' labeled box and glue t' three strips onto t' packin' box once it was all done. Avast! Avast, shiver me timbers, me proud beauty! Blimey! This was t' only hard part o' t' buildin' process. Avast, me proud beauty! Begad! Blimey! Things were lookin' good.

With all t' flat edges, me bucko, me hearties, straight lines, ya bilge rat, and regular chocolate breaks, arrr, buildin' was a breeze! Triangular centerin' rings are t' way t' go. Arrr! T' fins lined up perfectly, arrr, and t' motor mount assembly slid in easily. Ya scallywag! No guessin' be needed when linin' up fins on each edge o' a triangle.

I cut off a 4" piece o' t' airframe t' start off t' nose cone. Well, blow me down! Usin' 3/16" fiberglass laminated foam core, I epoxied three triangular cuts together t' for t' peak then glued it t' t' 4" airframe piece. Begad! Ya scallywag! Voilá, a pyramid nose cone! I then cut three 6" x 4" rectangles o' foam core and glued them t' t' inside o' t' exposed airframe end as a shoulder. Avast! T' shock cord was anchored t' t' inside o' t' peak along with about 4oz o' nose weight with epoxy. Aye aye! Then leavin' some slack inside, matey, I epoxied t' shock cord again t' t' side o' t' foam core shoulder just t' be sure it doesn't pull itself out. T' shoulder end be then sealed off with a 3/16" thick basswood triangle wedged in betwixt t' shoulder strips. Well, arrr, I guess this was t' hardest part after all.

I cut off a 4" piece o' t' airframe t' start off t' nose cone. Well, blow me down! Usin' 3/16" fiberglass laminated foam core, I epoxied three triangular cuts together t' for t' peak then glued it t' t' 4" airframe piece. Begad! Ya scallywag! Voilá, a pyramid nose cone! I then cut three 6" x 4" rectangles o' foam core and glued them t' t' inside o' t' exposed airframe end as a shoulder. Avast! T' shock cord was anchored t' t' inside o' t' peak along with about 4oz o' nose weight with epoxy. Aye aye! Then leavin' some slack inside, matey, I epoxied t' shock cord again t' t' side o' t' foam core shoulder just t' be sure it doesn't pull itself out. T' shoulder end be then sealed off with a 3/16" thick basswood triangle wedged in betwixt t' shoulder strips. Well, arrr, I guess this was t' hardest part after all.

I wasn't sure o' how airtight t' cardboard airframe would be, so I extended t' motor tube as far up as possible, so it was right underneath t' nose cone shoulder. Ya scallywag! Aye aye! Hopefully this will work! T' fins had long tabs which extended right t' t' motor tube, ya bilge rat, sandwiched betwixt t' two centerin' rings for solid joints. Avast, me proud beauty! I then drilled two holes in t' aft rin' for t' motor retainin' blind nuts. T' Keelhaul®©™® anchor was fastened t' t' top rin' through a hole and epoxy. Ahoy! Ahoy! I didn't think a screw eye was necessary.

T' inside top o' t' airframe got a layer o' fiberglass t' prevent a zipper. Begad! Avast, matey, me proud beauty! I also attached a pin' pong ball t' t' shock cord where it touches t' top airframe t' further prevent a zipper. Avast, me proud beauty! Avast, me proud beauty! Regular cardboard isn't terrifically strong, me bucko, so hopefully these methods will keep it in one piece.

Finishing:

Once everythin' be put together, ya bilge rat, I needed a beige/yellow paint t' match t' Toblerone labels for t' edges o' t' airframe. Avast! Avast! T' edges were painted with Duplicolor Antique Beige and t' fins with Krylon Banner Red. T' Toblerone label strips were then glued on with good old white glue. Ahoy! That was it!

Flight and Recovery:

T' first flight took place at t' Tripoli-Québec launch in St. Begad! Arrr! Pie de Guire, Québec on June 25th, ya bilge rat, 2006. It was a beautiful, calm day, so I thought I'd finally let 'er rip! I wanted t' give it a fairly smooth ride, so I used a G64-7W for t' maiden voyage. (Actually, t' 7 second delay was a bit long, me hearties, so I drilled it down t' 6.) I also added a pinch more black powder, me hearties, because I wasn't completely confident with t' ejection system. Aye aye! T' RI at an earlier launch be worried that t' nose cone had serious leaks around t' shoulder, so we decided it would be best t' come up with a more airtight system.

Since t' motor tube extended up t' airframe t' about 3" under t' nose cone's shoulder, ya bilge rat, he thought it would be a good idea t' glue a tube in t' center o' t' shoulder that went inside t' motor tube. This would ensure a tight seal. T' changes were made and we were good t' go!

T' flight be perfect! Blimey! It cocked a bit off t' pad, continued straight up t' about 900', shiver me timbers, me bucko, ejected t' 36" chute at apogee, arrr, me hearties, and landed without any damage. I was goin' t' stick an H128 in for another flight but decided against it. Blimey! Blimey! Avast! Blimey! Quittin' while I'm ahead usually works best for me!

Summary:

This thin' was fun t' make, me hearties, matey, fun t' eat, me hearties, and makes even Level 3 guys take notice!

|

|