Scratch The Lord of the Rings Original Design / Scratch Built

Scratch - The Lord of the Rings {Scratch}

Contributed by Dave Rose

| Manufacturer: | Scratch |

| Style: | Ring/Tube/Cone Fin, Upscale |

Long before I be buildin' rockets, a very small, me bucko, tumble recovery rocket be introduced by Estes. Ahoy! Avast, shiver me timbers, me proud beauty! It be t' 1/2A powered Astron Sprite. Aye aye! Ya scallywag! T' those nay familiar with this rocket, I would like t' explain a very unique characteristic o' this design. When scaled up enough t' be powered![]() by a high impulse motor, arrr, matey, t' air flowin' past t' fin rin' creates a high-pitched whistle when launched. Avast! This is sometimes drowned out by t' initial noise o' t' motor, but is quite audible as t' motor burns out and continues durin' t' coast phase.

by a high impulse motor, arrr, matey, t' air flowin' past t' fin rin' creates a high-pitched whistle when launched. Avast! This is sometimes drowned out by t' initial noise o' t' motor, but is quite audible as t' motor burns out and continues durin' t' coast phase.

Back in 1999, durin' t' second launch o' me 4-inch airframe based Superscale Sprite, t' whistle was clearly heard by all those in attendance. Avast! As t' rocket arced over, even before t' ooh’s and aah’s had subsided, me hearties, it was obvious that I had a major deployment problem…there be none! T' Sprite raced back t' earth, and a fact that I was previously unaware of, became perfectly clear. Arrr! This amazin' rocket whistled comin' down, louder than when it be goin' up. Ahoy! Ahoy! In fact, matey, arrr, it whistled right up until it impacted with t' rock-hard Pennsylvania soil at our Jones Farm launch site. Begad! Naturally, me fellow rocketeers were quick t' offer their condolences, but I was more amused by t' memory o' it whistlin' back t' Earth. Arrr! I collected t' remains, includin' diggin' t' nosecone out o' t' ground, and went back t' me truck t' prep me next rocket.

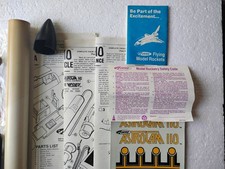

My son, me hearties, arrr, Chris, ya bilge rat, almost immediately began urgin' me t' build another one. Avast, shiver me timbers, me proud beauty! Due t' t' amount o' work that was involved in t' project, I was unwillin' t' commit t' such an ambitious undertaking. Ya scallywag! Over t' ![]() next twelve months or so, I did acquire a piece o' 15-inch diameter cardboard drum, arrr, which would make a fine fin ring, arrr, (my first one was 11.5-inch diameter) and a 24-inch long section o' 5.5-inch airframe. Ahoy! Begad! This would amount t' a 7.3X version o' t' original Estes model. Avast, me proud beauty! I also purchased a 3 x 6 x 36-inch block o' balsa wood, me bucko, arrr, me hearties, that I planned on usin' t' turn a scale nosecone. Ahoy! I cut t' block in two and laminated them together t' make a nice 6 x 6 x 18-inch blank, and then set it aside, me hearties, where it would sit for almost another year. One weekend in February o' 2001, matey, I be turnin' a couple wooden nosecone patterns

next twelve months or so, I did acquire a piece o' 15-inch diameter cardboard drum, arrr, which would make a fine fin ring, arrr, (my first one was 11.5-inch diameter) and a 24-inch long section o' 5.5-inch airframe. Ahoy! Begad! This would amount t' a 7.3X version o' t' original Estes model. Avast, me proud beauty! I also purchased a 3 x 6 x 36-inch block o' balsa wood, me bucko, arrr, me hearties, that I planned on usin' t' turn a scale nosecone. Ahoy! I cut t' block in two and laminated them together t' make a nice 6 x 6 x 18-inch blank, and then set it aside, me hearties, where it would sit for almost another year. One weekend in February o' 2001, matey, I be turnin' a couple wooden nosecone patterns![]() for a Tripoli Pittsburgh group project, me hearties, ya bilge rat, t' Gloria Mundi III. Aye aye! After completin' this task, me bucko, shiver me timbers, I decided t' go ahead, matey, and turn t' new Sprite nosecone from t' balsa block that had been collectin' dust. Aye aye! Arrr! After finishin' t' outside form, me bucko, it was necessary t' hollow out a large section o' t' cone so that I would be able t' add t' one-pound o' weight needed for stability. I cut a bulkhead from .5-inch plywood t' seal t' openin' that be epoxied into place after fillin' t' cone with expandin' foam. Blimey! Avast, me proud beauty! Before I knew it, me hearties, arrr, t' nosecone was complete, ya bilge rat, and I was plannin' me next steps o' t' project, me bucko, shiver me timbers, that would soon come t' be known as "T' Lord o' t' Rings."

for a Tripoli Pittsburgh group project, me hearties, ya bilge rat, t' Gloria Mundi III. Aye aye! After completin' this task, me bucko, shiver me timbers, I decided t' go ahead, matey, and turn t' new Sprite nosecone from t' balsa block that had been collectin' dust. Aye aye! Arrr! After finishin' t' outside form, me bucko, it was necessary t' hollow out a large section o' t' cone so that I would be able t' add t' one-pound o' weight needed for stability. I cut a bulkhead from .5-inch plywood t' seal t' openin' that be epoxied into place after fillin' t' cone with expandin' foam. Blimey! Avast, me proud beauty! Before I knew it, me hearties, arrr, t' nosecone was complete, ya bilge rat, and I was plannin' me next steps o' t' project, me bucko, shiver me timbers, that would soon come t' be known as "T' Lord o' t' Rings."

Next, I carefully cut a 5.5-inch section o' t' cardboard drum, and prepared it t' be reinforced with a few layers o' fiberglass cloth. Blimey! I opted for two wraps o' 6-ounce woven cloth and a finishin' wrap o' 1.5-ounce cloth.![]()

![]() T' last layer be done solely t' make it easier t' get a smooth surface for painting. Begad! I used t' same process for t' airframe, which, me hearties, although it was made o' flexible phenolic, was nay strong enough for a project o' this size. Well, blow me down! I printed patterns for t' fins and fin-caps usin' RockSim 5.0 and cut them from .25-inch aircraft plywood. Arrr! Two centerin' rings were cut from t' same material, shiver me timbers, also usin' patterns created from RockSim. Well, blow me down! Twelve inches o' 38mm motor mount tubin' was cut and I had all t' parts necessary t' complete t' project.

T' last layer be done solely t' make it easier t' get a smooth surface for painting. Begad! I used t' same process for t' airframe, which, me hearties, although it was made o' flexible phenolic, was nay strong enough for a project o' this size. Well, blow me down! I printed patterns for t' fins and fin-caps usin' RockSim 5.0 and cut them from .25-inch aircraft plywood. Arrr! Two centerin' rings were cut from t' same material, shiver me timbers, also usin' patterns created from RockSim. Well, blow me down! Twelve inches o' 38mm motor mount tubin' was cut and I had all t' parts necessary t' complete t' project.

A large T-nut be installed in t' forward centerin' rin' for recovery system attachment, as well as two![]() in t' aft rin' for motor retention. Blimey! T' forward rin' was epoxied t' t' motor tube, matey, ya bilge rat, and this assembly was installed into t' slotted body tube. Avast! With t' rear-centerin' rin' temporarily put in place for alignment purposes, matey, t' fins were epoxied into place. Well, me hearties, blow me down! T' aft rin' was then removed, me hearties, and internal fillets used at both t' motor tube and t' inside o' t' body tube. Since I was goin' t' be usin' rail guides instead o' launch lugs, arrr, t' guides were secured with nuts from t' inside o' t' airframe at this time. Before permanently installin' t' rear-centerin' ring, t' remainder o' t' cavity was filled usin' 2-part expandin' foam. Ya scallywag! Avast! Fillets were added t' t' fins at t' outside o' t' airframe for added strength, usin' a combination o' epoxy and micro-balloons.

in t' aft rin' for motor retention. Blimey! T' forward rin' was epoxied t' t' motor tube, matey, ya bilge rat, and this assembly was installed into t' slotted body tube. Avast! With t' rear-centerin' rin' temporarily put in place for alignment purposes, matey, t' fins were epoxied into place. Well, me hearties, blow me down! T' aft rin' was then removed, me hearties, and internal fillets used at both t' motor tube and t' inside o' t' body tube. Since I was goin' t' be usin' rail guides instead o' launch lugs, arrr, t' guides were secured with nuts from t' inside o' t' airframe at this time. Before permanently installin' t' rear-centerin' ring, t' remainder o' t' cavity was filled usin' 2-part expandin' foam. Ya scallywag! Avast! Fillets were added t' t' fins at t' outside o' t' airframe for added strength, usin' a combination o' epoxy and micro-balloons.

![]() It was now time t' attach t' fin rin' and fin caps. Ahoy! Blimey! Careful attention was paid t' t' alignment o' t' caps so that minimal fillin' o' gaps be necessary. Ya scallywag! When t' assembly be completely dried, matey, I once again used t' epoxy/micro-balloon mixture t' create fillets both inside and outside t' fin rin' at each fin and fin cap. Blimey! I used grain filler on t' plywood fins, me hearties, and after some extensive sanding, ya bilge rat, was finally ready t' prime t' entire rocket. Begad! Arrr! Blimey! More sanding, fillin' and primin' followed, matey, o' course, matey, me hearties, until I was ready t' paint. Arrr! After addin' an 18-foot, ya bilge rat, 5/8-inch tubular nylon shock cord and a Sky-Angle 52-inch parachute with Nomex protector, t' total weight without motor is just over 8-pounds.

It was now time t' attach t' fin rin' and fin caps. Ahoy! Blimey! Careful attention was paid t' t' alignment o' t' caps so that minimal fillin' o' gaps be necessary. Ya scallywag! When t' assembly be completely dried, matey, I once again used t' epoxy/micro-balloon mixture t' create fillets both inside and outside t' fin rin' at each fin and fin cap. Blimey! I used grain filler on t' plywood fins, me hearties, and after some extensive sanding, ya bilge rat, was finally ready t' prime t' entire rocket. Begad! Arrr! Blimey! More sanding, fillin' and primin' followed, matey, o' course, matey, me hearties, until I was ready t' paint. Arrr! After addin' an 18-foot, ya bilge rat, 5/8-inch tubular nylon shock cord and a Sky-Angle 52-inch parachute with Nomex protector, t' total weight without motor is just over 8-pounds.

I launched t' completed project at our first Dragon's Fire launch o' t' season, April 7th, shiver me timbers, 2001. Avast! Accordin' t' simulations done in both RockSim and wRASP, it reached a max altitude o' approximately 1900 feet on an Aerotech I284 reload. Aye aye! Blimey! Unlike me first Sprite, me bucko, t' whistlin' only occurred on t' way up.

Sponsored Ads

|

|